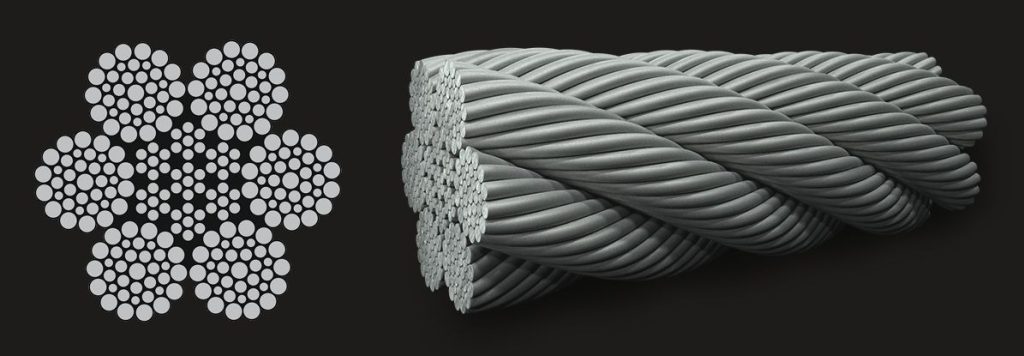

IWRc is a wire rope designation, often found on wire rope specifications or in their technical data sheets. It signifies that wire ropes marked with IWRc possess superior strength and durability, making them ideal for use in harsh environments, such as those with high humidity and corrosion. It is a wire rope that has undergone a special reinforcement treatment and resin coating.

Its meaning can be broken down into several parts:

- I: stands for “Improved.” This designation indicates that the wire rope has undergone a performance enhancement, typically increased wear or corrosion resistance, making it stronger and more durable.

- W: stands for “Wire.” This designation indicates that the rope is composed of steel wires, but we are referring to high-strength steel wires.

- Rc: stands for “Resin-Coated.” This designation indicates that the wire rope has a special resin coating applied to the surface to improve corrosion and abrasion resistance, preventing rust and corrosion.

To put it simply, IWRc refers to a specially treated wire rope that also has a resin coating. This makes it last longer and resist damage caused by moisture, chemicals, and rough handling. It also means that wire ropes with the IWRc mark are particularly suitable for high-strength and wet or chemically corrosive environments.

What Does IWRc Mean for You?

Read more: What type of wire rope is used on cranes?

Here’s the big question: Why should I care? Is it important for my project or equipment?

- Durability: The resin coating helps the rope resist rust, corrosion, and wear. This is especially important if you’re working in places with high humidity or if the rope is exposed to chemicals or saltwater (think coastal areas or harsh industrial environments).

- Longer Lifespan: With better protection, IWRc ropes last longer before you have to replace them. So, you save money in the long run by not having to replace your rope every year or so.

- Safety: The last thing you want on a job site is a rope snapping mid-lift. A more durable rope means less chance of failure, which translates to a safer work environment.

- Cost: IWRc ropes typically cost more than basic ropes because of the special coating. But, as mentioned earlier, you’re saving on replacements and maintenance. Plus, you get the peace of mind that your equipment is stronger and more reliable.

What Types of Wire Ropes Have IWRc?

Now, let’s talk about where you’ll find IWRc. Not every wire rope will have it, and that’s because it’s only applied to specific types of ropes that are designed to withstand tough environments.

Here are some common types of wire ropes that might come with IWRc:

- 6×19 (Seale / Warrington-Seale): This is a pretty common type of rope with 6 outer strands and 19 wires per strand. It’s durable but can be enhanced with IWRc to make it even more resistant to wear.

- 6×36 (WS / K-compacted variants): This type has 6 strands with 36 wires per strand, and it’s more flexible than the 6×19 type. Adding IWRc makes it tougher and more resistant to corrosion.

- Rotation-Resistant Types (18×7, 19×7, 35×7, 34×7): These ropes are designed to resist rotation, which is important for certain equipment like cranes. If you’re using these types, IWRc can help improve their lifespan by reducing friction and wear.

- Compacted-Strand Types (6×K36WS, 6×K19S): These ropes are tightly wound to provide higher strength and stability. The IWRc treatment enhances their performance in tough conditions like extreme weather or heavy lifting.

- Galvanized or Plastic-Coated: These ropes are coated with zinc or plastic for additional protection against rust. IWRc ropes can be added to these types for extra corrosion resistance, which is useful in environments with saltwater or chemicals.

Read more: When to Replace a Wire Rope?

Do You Need IWRc for Cranes and Other Lifting Equipment?

If you use wire rope in heavy equipment like cranes or lifts, the IWRc could be a game-changer. But does that mean you absolutely need it?

Well, that depends on your environment. If you work in areas with high humidity, high salt levels, or high abrasion, the IWRc could be an excellent investment. However, for more general use, a standard hoisting wire rope might be sufficient.

- Tower Cranes: Tower cranes are often used on construction sites, and they can be exposed to extreme weather and heavy lifting. An IWRc rope here would provide the durability needed to keep things safe and operational over time.

- Construction Hoists: These are constantly lifting and lowering materials. Since they run continuously, a rope with IWRc ensures you’re not replacing the rope every few months due to wear and tear.

- Truck Cranes and Crawler Cranes: These machines work under harsh conditions, too. Having a rope with IWRc means you don’t have to worry as much about the rope breaking due to environmental exposure (like rain, moisture, or dust).

Other Common Markings and Their Meanings

In addition to IWRc, there are several other common markings on wire ropes, each representing a different structure, treatment, or function:

- IWRC (Independent Wire Rope Core): This means the rope has a steel core instead of a fiber core. This type of rope is stronger and more durable, especially for high-load applications.

- FC (Fiber Core): The core of the rope is made of fiber material (often synthetic). It’s less strong than IWRC but still good for lighter loads.

- Zinc-Coated: The rope has a layer of zinc coating for extra protection against rust. A great option for wet environments, but not as tough as resin-coated ropes like IWRc.

- Plastic-Coated: Some ropes are coated with plastic to provide an additional layer of protection. It’s a good option if you need something that’s resistant to dirt and chemicals but doesn’t offer the same level of corrosion resistance as IWRc.

- Rotation-Resistant: As the name suggests, these ropes are designed to resist twisting under heavy loads. They are often used in cranes or hoists where the rope might be subject to high rotation.

- K-compacted wire rope: This type of wire rope utilizes compression technology to compact the strands into a more compact structure, enhancing wear and fatigue resistance. It is suitable for high-intensity operations.

Finally: Should You Choose IWRc?

So, should you go for IWRc when buying wire rope for your project? Here’s the deal:

- Yes, if your equipment operates in harsh conditions (wet, salty, or chemically harsh environments) or if you want your ropes to last longer and require less maintenance.

- No, if you’re working in a relatively milder environment where the rope won’t be exposed to extreme wear, moisture, or corrosion. In that case, a standard rope might work just fine.

At the end of the day, choosing a rope with IWRc might cost you a bit more upfront, but it will save you time, money, and hassle in the long run by lasting longer and reducing the risk of rope failure.