Construction Passenger & Materials Hoists, also known as Material-Only Hoists, are among the most essential pieces of lifting equipment on any jobsite. For construction hoists, performance is important, but safety features are what protect your crew and ensure your equipment remains compliant.

If you are seeking to equip a construction hoist with the required safety devices, for construction hoists, the core safety devices that are required include a fall arrest device, overload limiter, speed governor, limit switches, emergency stop system, safety interlocks, safety hooks, anti-tilt protection, and buffers. For construction hoists used on high-rise or heavy-duty projects, wind speed sensors, alarm systems and IoT Monitoring devices are highly recommended.

These devices are not optional or just a “suggestion” to keep your crew and equipment compliant. They are designed to ensure that the hoist does not overspeed, overload, tilt, crash, drop, or operate under hazardous conditions. Without them, compliance and the safety of your crew will be put at high risk or at a total loss.

What Are the Crane Safety Devices for Construction?

| Safety Device | Core Function | Mainly Used On | Why It Matters | What to Check Before Buying |

| Fall Arrest Device | Prevents the cage from hitting the top frame | Passenger & Material Hoists | Prevents deadly accidents | Certification, arresting speed, compatibility |

| Overload Limiter | Stops hoist when overloaded | Both | Protects motor & gearbox | Accuracy, display type, cut-off logic |

| Speed Governor | Monitors high-speed movement | Passenger hoists | Prevents overspeed travel | Activation speed, sensor reliability |

| Limit Switches | Prevents top/bottom impact | Both | Avoids collision & equipment damage | IP rating, mechanical strength |

| Emergency Stop Button | Instant shutdown | Both | Critical during emergencies | Button quality & placement |

| Electrical Safety Circuit | Safe interlock operation | Both | Prevents unsafe starts | Redundant design |

| Buffer / Shock Absorber | Reduces bottom impact force | Both | Safety backup system | Material compression level |

| Safety Hook | Prevents derailment | Material hoists | Secures the cage on the mast tower | Locking strength |

| Anti-Tilt Monitor | Detects abnormal tilting | Passenger hoists | Prevents derailment accidents | Sensor sensitivity |

| Anti-Top Protection | Tracks load, alarms, and runtime | Both | Mandatory for high-rise hoists | Dual switch design |

| Anemometer | Measures wind speed | High-rise hoists | Prevents wind-related accidents | IP67 rating, alarm setting |

| Smart Alarm System | Detects hidden failures | Heavy-duty sites | Early warning for damage | Sensor thresholds |

| IoT Remote Monitoring | Tracks load, alarms, runtime | Rental fleets | Prevents failure & reduces downtime | Tracks load, alarms, and runtime |

Core Safety Devices (Required by most standards)

- Fall Arrest Device

- Overload Limiter

- Speed Governor

- Limit Switches (Upper/Lower)

- Emergency Stop Button

- Electrical Safety Circuit

- Buffer / Shock Absorber

- Safety Hooks

- Anti-Top Protection

Advanced Protection Devices

- Anti-Tilt Monitor

- Smart Alarm System (temperature, vibration, electrical faults)

High-Level Monitoring Systems

- Wind Speed Sensor (Anemometer)

- IoT Remote Monitoring System

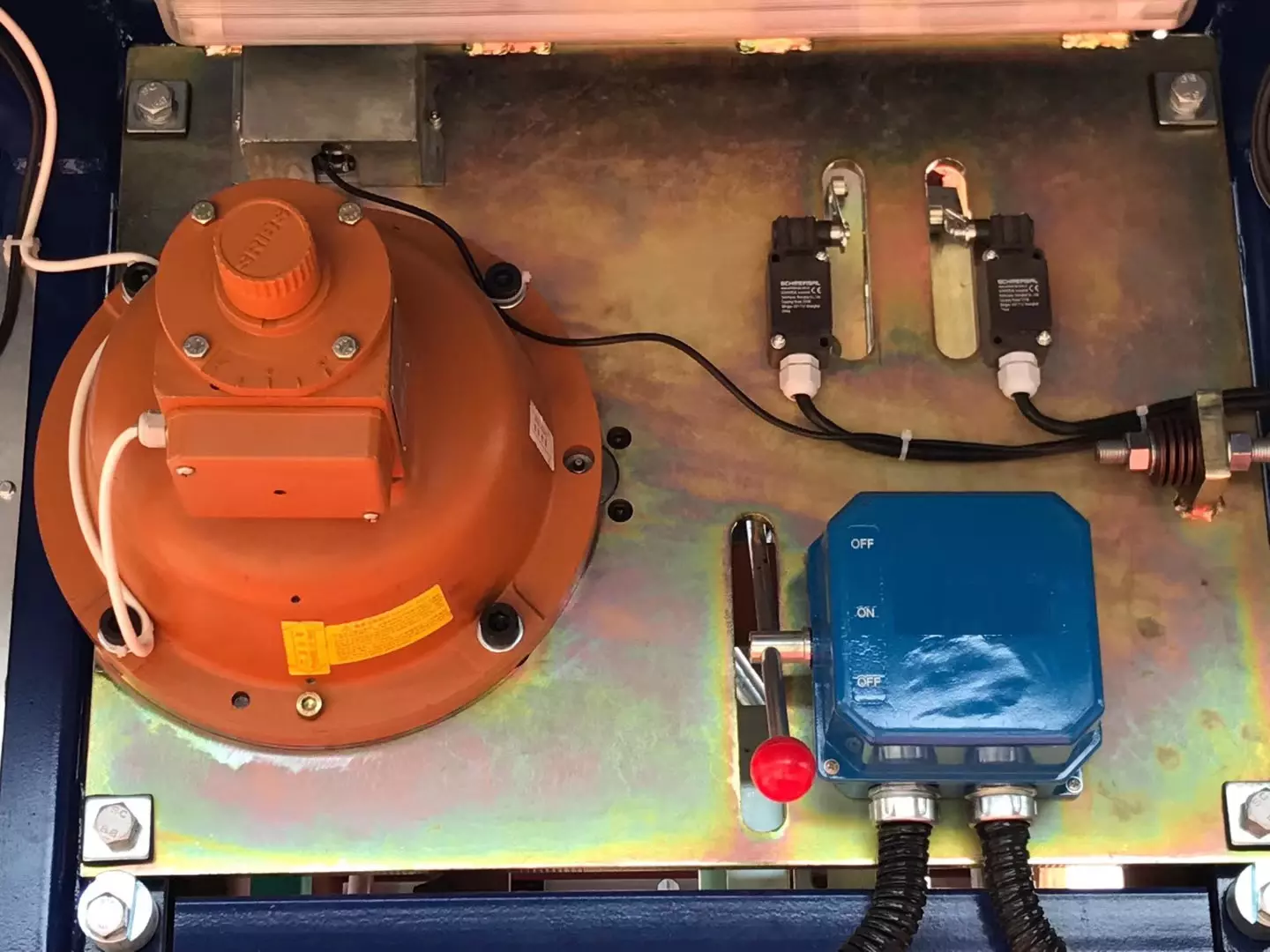

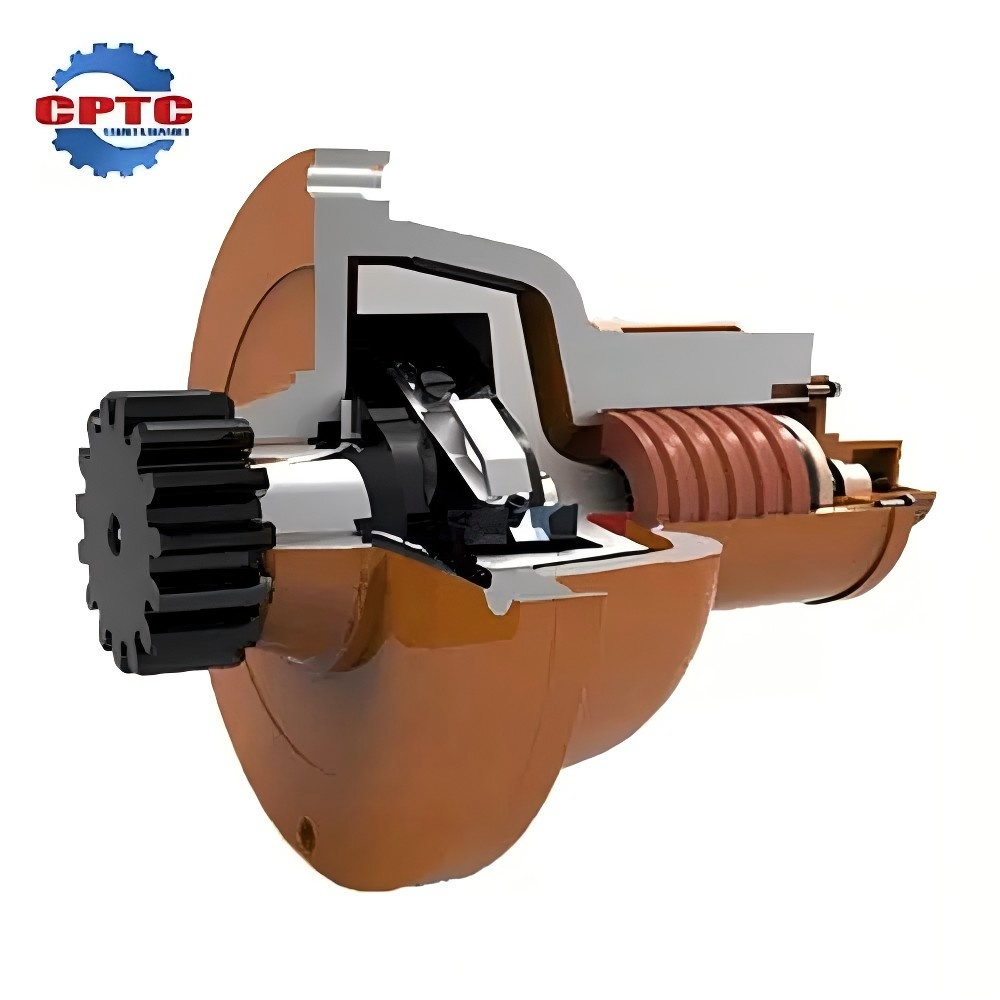

Fall Arrest Device

How It Works (Simple Explanation)

A mechanical centrifugal system detects overspeed. When speed exceeds the safety limit, it immediately locks onto the rack and stops the cage.

Advantages

- Works even during a power failure

- Very high reliability

- Mandatory for all passenger hoists

Limitations

- Requires regular calibration

- Must match rack & pinion specifications

Key Specs to Check

- Arresting speed

- Rated load

- Certification (EN 12159 / GB/T 26557)

- Calibration validity

Buying Tips

- Always ask for the test report

- Choose devices compatible with your mast rack.

- Select models with stable mechanical structures.

Common Mistakes

- Using “universal” devices without checking pinion compatibility

- Not recalibrating on time

- Buying low-cost devices with no certification

Overload Limiter

How It Works

Sensors detect load → controller compares with rated capacity → hoist shuts down if overloaded.

Advantages

- Protects electrical systems

- Avoids mechanical stress

- Prevents structural damage

Limitations

- Accuracy varies by brand

- Sensors require proper calibration

Key Specs to Check

- ±1–3% accuracy

- Display type (digital preferred)

- Alarm + auto-stop logic

Common Mistakes

- Thinking that an “alarm only” model is enough

- Incorrect sensor placement

- Ignoring recalibration after floor plate changes

Speed Governor

How It Works

Monitors cage movement speed → sends signal → safety system triggers brake if speed exceeds limit.

Advantages

- High accuracy

- Required for most passenger hoists

Limitations

- Mechanical governors wear out

- Electronic governors need stable power

Key Specs

- Activation speed

- IP rating

- Sensor type

Common Mistakes

- Choosing the wrong activation speed

- Using mechanical sensors in high-rise projects

Limit Switches

How They Work

Activated when the hoist reaches top or bottom limit. Prevents travel beyond safe positions.

Advantages

- Simple

- Reliable

- Low maintenance

Key Specs

- Waterproof level (IP65+)

- Contact life cycles

- Mechanical durability

Common Mistakes

- Only using a single top limit

- Buying cheap plastic switches

- Poor wiring quality

SRIBS Safety Device vs Alimak vs STROS

Here is first-hand information to allow better decision-making, especially when using STROS or Alimak hoists.

When it comes to reliable fully integrated safety devices at a competitive price, manufactured at the same level as international competition, safety devices by SRIBS deliver the best value for money.

| Feature | SRIBS Safety Devices | Alimak OEM Devices | STROS OEM Devices |

| Compatibility | Compatible with Alimak, STROS, GEDA, Zoomlion, Maber | Alimak-only | STROS-only |

| Certification | EN 12159, EN 81-20, GB/T 26557, ISO9001 | EN / CE | EN / CE |

| Product Range | Fall arrest, overload limiter, governor, limit switches, IoT | Mainly OEM components | Mainly OEM components |

| Pricing | More cost-effective | High OEM pricing | High OEM pricing |

| Spare Parts | Universal spares, fast delivery | OEM parts only | OEM parts only |

| Calibration | Factory test + report | OEM calibration | OEM calibration |

| Long-Term Cost | Lower maintenance cost | Higher lifecycle cost | Higher lifecycle cost |

| Ideal For | Mixed-brand fleets, rental companies | Alimak equipment owners | STROS equipment owners |

Why Many Buyers Choose SRIBS for Construction Hoists?

- Works as a direct replacement for Alimak & STROS safety devices

- Universally compatible across multiple brands

- Strong mechanical construction for longer service life

- Lower cost without sacrificing certification

- Faster delivery + easier spare parts support

- Available for both new installation and aftermarket retrofit

SRIBS is especially popular among rental companies and international contractors who run different hoist brands and want a standardized, cost-efficient safety device solution.

How to Choose the Right Safety Devices for Your Construction Hoist?

| Project Type | Must-Have Devices | Recommended Upgrades | Why |

| High-Rise Building | Fall arrest, limit switches, overload limiter | Wind sensor, IoT monitoring, CCTV | Wind & height risks |

| Passenger Transport | Full safety system + speed governor | Anti-tilt + black box | Stable travel required |

| Material-Only Hoist | Limit switches, overload limiter | Smart alarms, safety hooks | Heavy loads |

| Rental Fleet | Universal limit switches + overload limiter | IoT monitoring | Track run-time, reduce breakdowns |

| Government Projects | All mandatory devices + certifications | Documentation ready | Compliance inspections |

Things to Confirm Before You Buy

- Do they hold certification (EN/GB/ISO)?

- Will they work with your brand of hoist?

- Do they provide calibration reports?

- How quickly can you acquire spare parts?

- Is the warranty period at least 12 months?

- Will the supplier provide assistance with installation?

- Is the product appropriate for the conditions of your job site (wind, height, load)?

If you operate with multiple brands of hoists, for instance, Alimak, STROS, GEDA, Zoomlion, Maber, our recommendation would be to go with a cross-compatible type SRIBS, it will ultimately lead to further cost efficiency and ease of maintenance.

Final

The construction hoists’ safety devices are not merely optionalthey are the requisite to safe and efficient lifting operation. Their correct selection not only ensures the safety of workmen but also minimises unnecessary breakdowns, decreases the required maintenance, and keeps the project within the legally required operating framework.

- Protect workers with the correct safety devices

- Understand the purpose served by each device

- Acknowledge the reason each hoist requires the installation of differing types of protective devices

- Compare brands, then make an informed selection

- Understand why SRIBS is a viable alternative to Alimak and STROS

- Know which configuration is best suited to various job site scenarios

By paying attention to safety, compatibility, certification, and reliability over the year, you will, without a doubt, end up choosing the best available safety devices for your construction hoist.