If you operate a construction hoist, a key question you may be asking yourself is:

- “What is the safe operating length for my hoist crane wire rope?”

- Total Rope Length = (Lift Height x Number of Falls) + Drum Reserve + Dead Length

The following guide is specifically designed for hoist operators, project managers, and individuals needing to understand the appropriate wire rope length and avoid costly errors.

What Happens If Your Wire Rope Is Too Long or Too Short?

Make sure your rope is just right. Consider safe lifting height + drum reserve + routing. You want to have enough to work with, but it shouldn’t be so much that it piles up.

Getting rope length wrong can create real safety risks.

If the rope is too short(safety hazards)

| Risk | Description |

| Hoist cannot reach the full lifting height | The platform may stop before the required top level. |

| Over-tension on the rope | The drum may pull the rope too tight, accelerating wear. |

| Unsafe operating conditions | The rope may run out before the drum stops → extremely dangerous. |

If the rope is too long (mechanical issues)

| Risk | Description |

| Rope piles up on the drum | Extra rope has no place to go → overlapping, crushing, kinking. |

| Faster rope wear & broken strands | Rope rubbing on rope is one of the fastest ways to destroy it. |

| Hoist may jerk or slip | Irregular winding causes shock loads. |

| Maintenance costs increase | You’ll replace the rope far earlier than expected. |

How to Calculate Crane Wire Rope Length for a Construction Hoist?

Basic Formula (No complicated math):Total Rope Length = (Lift Height × Number of Falls) + Drum Reserve + Dead Length

Lift Height

- This part is easy — it’s the maximum height your hoist needs to travel.

- Example:80 meters lifting height → at least 80 meters of rope per fall.

Number of Falls (Rope Parts)

This is the most misunderstood part — and the biggest multiplier. Your hoist may use:

- Single-fall (1 rope line)

- Two-fall (2 rope lines)

- Four-fall (4 rope lines)

- More falls = more rope needed.

Example

- 80m lifting height

- Two-fall system → 80m × 2 = 160m base rope length.

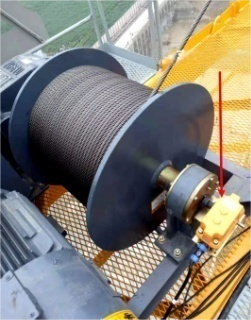

Drum Reserve (Mandatory Safety Turns)

To prevent the rope from slipping or pulling out from the drum, you must keep:

- 2–3 full wraps on the drum at all times.

- This typically adds:1–2 meters (depending on drum diameter)

Dead Length (Fixed Rope Path Inside the Hoist)

Every hoist has a fixed distance of rope already used inside the machine:

- Drum to main sheave

- Sheave to lifting point

- Tensioning system

This distance is usually 1–3 meters. Example Calculation (Very Practical):

- Lift height: 80 m

- Rope system: 2 falls

- Drum reserve: 2 m

- Dead length: 2 m

Total Rope Length = (80 × 2) + 2 + 2 = 164 m; In real purchasing:165–170 m is perfect.

What Is the Typical Wire Rope Length Used on Construction Hoists?

Below is a general reference based on common hoist heights around the world.

Typical Rope Lengths by Hoist Lifting Height (Two-Fall System)

These include drum reserve + dead length + a small safety allowance.

| Hoist Lifting Height | Typical Rope Length (2-Fall) |

| 50 m building | 105–115 m |

| 80 m building | 165–175 m |

| 100 m building | 205–215 m |

| 150 m building | 305–320 m |

| 200 m building | 405–420 m |

Typical Rope Lengths for Standard Construction Hoists

| Hoist Height | Common Falls | Typical Rope Length Range |

| 30–40 m | 1–2 falls | 40–90 m |

| 50–60 m | 2 falls | 110–130 m |

| 80–100 m | 2–4 falls | 160–260 m |

| 100–150 m | 4 falls | 300–500 m |

| 200+ m | 4 falls | 500–800 m |

Hoist uses a 4-fall rope routing

Just double the number above.

How to Choose the Right Crane Wire Rope for a Construction Hoist?

Length is only the first step — but choosing the correct rope type is just as important. Here are practical, fast-check tips:

Choose the correct rope diameter

- Must match the drum groove & sheave groove.

- Wrong diameter = accelerated wear or slippage.

Choose the correct construction (6×19 / 6×36 / 8×19)

- More wires → more flexibility

- Fewer wires → more durability

Choose steel core (IWRC) for hoists

It handles higher loads and heat generated on the drum.

Choose galvanized rope for outdoor construction

Lasts longer in rain, dust, and humidity.

Buy from a supplier who understands hoists

This is a strong EEAT signal: expert support reduces risk.

Summary: How Long Should Your Crane Wire Rope Be?

Most hoist ropes fall between 40m and 500m, with an additional 5–10% extra for installation.Total Rope Length = (Lift Height × Falls) + Drum Reserve + Dead Length

- Too long → winding problems & rope damage.

- Too short → safety hazards & failed inspections.

Get the length right, and your construction hoist will run smoother, safer, and with fewer breakdowns.