You’re operating a mobile crane at a port, or a boom lift on a construction site, and a sudden 25mph (40km/h) gust hits. Your slewing brake starts slipping, or the platform begins rotating on its own. Do you lock the brake? Switch to free slewing? Ignore it and push through the job?

These are the split-second questions that separate safe operations from costly accidents. This blog cuts through the jargon to answer every urgent query you have: no engineering lectures, just clear decisions, 5-minute on-site checks, and step-by-step fixes for high-wind slewing brake issues.

Slewing Brake Safety & Free Slewing: What are they?

What Is a Slewing Brake—and What Is It Designed For?

A slewing brake is a component that locks your equipment’s rotating platform (slewing ring) in place. Its designed use is simple: prevent accidental rotation in low wind (≤10mph / 16km/h) — for example, when pausing a lift to reposition a load or secure cargo. Critical note: It is NOT built to resist the lateral force of strong winds.

What is Free Slewing? Why Is It Safer in High Winds?

Free slewing means disabling the active slewing brake, allowing the platform to rotate with the wind (not against it). It’s safer in high winds because:

- Strong gusts create enormous pressure on a locked platform — this pressure will warp brake components, crack the slewing ring, or burn out hydraulic/electric systems.

- Free slewing releases that wind force, reducing stress on all moving parts and preventing uncontrolled “snapping” rotations.

Lock Slewing Brake Safety or Free Slewing in High Wind?

This is the question you’re here to answer. Below is a quick-reference table for high-wind scenarios — no guesswork required:

| Wind Speed (MPH/KMH) | Job Status | Decision: Lock Brake or Use Free Slewing? |

| ≤10mph (16km/h) | Working / Paused | Lock the slewing brake (safe for low-wind stability) |

| 11-25mph (17-40km/h) | Working | Use free slewing (control rotation speed with the joystick; shorten the boom to reduce wind resistance) |

| 11-25mph (17-40km/h) | Paused | Switch to free slewing (never lock the brake) |

| ≥26mph (41km/h) | Any Status | Stop work immediately → Switch to free slewing → Retract boom/attachments → Secure the site |

When Must You Switch to Free Slewing?

- Wind speed jumps to ≥11mph (17km/h) — even if you’re mid-job.

- The slewing brake starts slipping, squealing, or triggering a warning light.

- You’re working in a “wind tunnel” (e.g., between tall buildings, in a valley) where gusts are unpredictable.

- The platform begins rotating on its own (this is wind forcing it — not a failure… yet).

What Happens If You Don’t Switch to Free Slewing?

- Component damage: Worn brake pads, broken springs, or leaking hydraulic lines (from wind pressure).

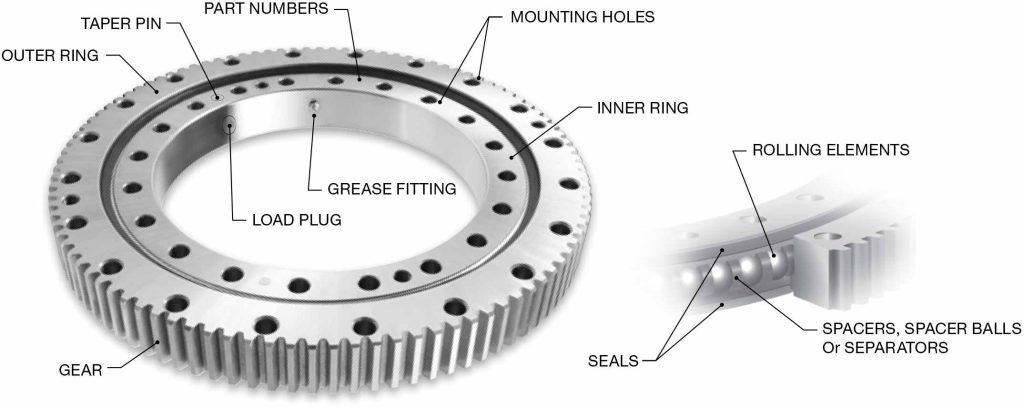

- Structural risk: Loose or cracked slewing rings (the core of your rotating system).

- Safety hazard: Uncontrolled sudden rotation that slams into workers, equipment, or structures.

Free Slewing vs. Brake Failure: Common Problems During High Wind

Slewing Ring for Tower Crane

- Fast delivery based on goods in stock

- Best quality based on careful inspection

- Export directly without 3RD company

One of the biggest frustrations is the platform rotating because you’re in free slewing mode (normal), or because the brake is failing (dangerous). Here’s how to tell the difference in 2 minutes:

| Feature | Free Slewing (Normal, Active Switch) | Slewing Brake Failure (Fault) |

| Rotation Behavior | Slow, steady rotation with the wind; joystick adjusts speed slightly | Uncontrolled, erratic rotation (fast/slow/sputtering); joystick has no effect |

| Associated Signs | No noise, no warning lights, smooth movement | Metal grinding/clunking, oil leaks, RED brake warning light on the control panel |

| Joystick Feedback | Consistent resistance; you can lock the brake again easily | Joystick feels loose (no resistance) or stiff (stuck); cannot re-engage the brake |

5-Minute On-Site Emergency Check (No Special Tools Needed)

Slewing Reducer for Tower Crane

- Fast delivery based on goods in stock

- Best quality based on careful inspection

- Export directly without 3RD company

If you’re unsure whether it’s a mode mix-up or a failure, run this quick test:

- Look: Check for the red brake warning light. Scan for oil leaks around the slewing ring or brake assembly.

- Feel: Grab the slewing joystick — does it have the same “give” as usual? Loose = hydraulic/electric issue; stiff = mechanical blockage.

- Listen: Lean in to the slewing area — grinding, or squealing means metal-on-metal contact (a fault).

- Test: Toggle between brake and free slewing modes. If you can’t lock the platform at all, it’s a failure.

- Confirm Wind: Estimate wind speed (use leaves/flags: brisk leaf movement = 10-15mph; flag fully extended = 20+mph).

Tiered Fault Response: Fix It Fast (and Safely)

Slewing Motor for Tower Crane

- Slewing Mechanism

- Ensures stability and safety

- Essential for construction sites

- Handles heavy materials

When a failure happens, follow this sequence: Safety First → Diagnose → Fix → Prevent. It’s designed to get you back up (or secure the site) in minutes.

Step 1: Emergency Action (Do This Within 5 Minutes)

Stop all work immediately — release the joystick and cut power to non-essential systems.

Switch to free slewing (even if the brake is failing) to reduce wind pressure.

- If rotation is uncontrolled: Evacuate workers to a safe zone (1.5x your equipment’s working radius) and set up a warning perimeter.

- If rotation is slow/steady: Temporarily secure the platform with wooden blocks (wedged between the slewing ring and base) or steel cables (anchored to a fixed structure).

Step 2: Fault Location — What’s Causing the Issue?

Diagnose whether it’s an operation, mechanical, or control system problem (no fancy tools required):

- Operation Issue: You forgot to switch to free slewing, or the joystick was bumped into the wrong mode. Fix: Double-check the mode switch and re-train if needed.

- Mechanical Issue: Worn brake pads, stuck release device, broken spring, or loose slewing ring bolts. Fix: Inspect and replace damaged parts (see below).

- Control System Issue: Low hydraulic pressure (hydraulic brakes), blown fuse (electric brakes), or a faulty control module. Fix: Troubleshoot fluid/power first (easy fixes) before calling a tech.

Step 3: Component-by-Component Troubleshooting & Fixes

Target the most common high-wind failures with quick, on-site solutions:

| Component | Common High-Wind Faults | Troubleshooting Step | Solution |

| Slewing Brake Pads | Slipping, fast wear, grinding | Remove the brake cover and check thickness (replace if <3mm) | Replace pads; adjust brake gap (turn the adjusting screw until pads touch the disc, then back off ¼ turn) |

| Brake Release Device | Stuck (can’t switch to free slewing) | Check for sand/dirt blocking the release lever | Clean debris with compressed air; apply lithium grease to the pivot point |

| Brake Spring | Broken, weak tension (brake won’t lock) | Inspect for cracks/deformation (look near the brake caliper) | Replace with a manufacturer-matched spring (carry spares for high-wind sites) |

| Hydraulic Brake System | Low pressure, oil leaks | Check hydraulic fluid level (use the sight glass); inspect hoses for cracks | Top up with the manufacturer-recommended fluid (e.g., ISO VG 46); tighten loose fittings or replace damaged hoses |

| Electric Brake System | No power, unresponsive switch | Check the fuse box (look for a labeled “slewing brake” fuse); inspect wiring terminals for corrosion | Replace blown fuses; clean corroded terminals with sandpaper and reattach |

Step 4: Root Fix — Prevent It From Happening Again

- Operation Issues: Add a pre-work checklist item to confirm slewing mode before starting.

- Mechanical Issues: Schedule weekly inspections of brake pads, springs, and slewing ring bolts.

- Control Issues: Test hydraulic pressure/electric connections monthly; replace aging hoses/wiring proactively.

High-Wind Mistakes to Avoid & Prevention Tips

Centrifugal Fan for Slewing Mechanism

- Dissipates heat

- Simple design

- Prevents overheating

- Ensures smooth operation

Dangerous Mistakes That Lead to Accidents

- Never lock the slewing brake when wind speed ≥11mph (17km/h) — this is the #1 cause of brake failure in high winds.

- Don’t force the platform to rotate against the wind (e.g., trying to swing into a gust) — this overloads every component.

- Ignore the brake warning light at your peril — it’s not a “nuisance” alert; it’s a sign of imminent failure.

- Don’t use free slewing as an excuse to keep working in ≥26mph (41km/h) winds — stop work and secure the equipment.

Prevention Tips (Reduce Faults by 80%)

- Weekly Checks: Inspect brake pad thickness, hydraulic fluid level, and slewing ring bolt tightness.

- Monthly Maintenance: Lubricate the brake release device and slewing ring; test the free slewing mode.

- Pre-Work Prep: Check the weather forecast and scan the site for wind tunnels (e.g., skyscraper gaps, valley entrances).

- Training: Ensure all operators know the wind speed thresholds and free slewing rules (print this guide and keep it in the cab).

Final

When wind hits, follow the wind — free slewing releases pressure, while locking the brake invites failure. If you suspect a fault, run the 5-minute check first, take emergency action, and troubleshoot components in order (pads → springs → fluid/power).

Save this guide to your phone for on-site reference, and share it with your team to eliminate guesswork. If you’re dealing with a specific equipment model (e.g., tower crane, boom lift, or port crane) with unique slewing issues, leave a comment below — I’ll share model-specific fixes tailored to your machine.

Tower Crane Slewing Device

Smooth Operation

Export directly without 3RD company

Slewing Ring for Tower Crane

Best quality based on careful inspection

Export directly without 3RD company

Slewing Reducer for Tower Crane

Best quality based on careful inspection

Export directly without 3RD company

Slewing Motor for Tower Crane

Ensures stability and safety

Essential for construction sites

Handles heavy materials

Flexible Coupling Rubber for Tower Crane

Slewing Mechanism

Compensates for errors

Good redundancy, shock absorption, noise reduction

Centrifugal Fan for Slewing Mechanism

Simple design

Prevents overheating

Ensures smooth operation