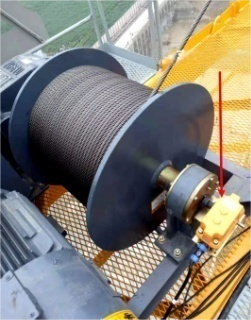

Hoisting Wire Rope for Tower Cranes

- Tower Crane Hoisting Mechanism

- Wide variety of specifications

- Construction Types: 6×36 IWRC, 8×19 Seale, or tailored per your project specs

- Wire Diameter Range: 12mm to 28mm

- Core Type: Steel Core (IWRC) – for better strength retention under heavy loads

- Surface Finish: Galvanized, bright, or plastic-coated options available

- Tensile Strength: Up to 1960 N/mm²

- Lubrication: Factory-lubricated to reduce internal friction and heat

Product Description

Built for Heavy-Duty Hoisting

Steel wire rope is a crucial component of tower cranes, responsible for lifting and transporting goods or materials. Its key characteristics include durability, high strength, corrosion resistance, and good flexibility. Its structure is typically divided into a core and strands, employing a wrapping structure to enhance overall strength and durability.

The high-quality steel wire ropes provided by CPTC are suitable for tower cranes.

Applications

Our hoisting wire ropes are engineered for:

- Luffing jib tower cranes

- Hammerhead tower cranes

- Flat-top tower cranes

- Customized lifting systems

Whether for a new installation or a wire rope replacement, I deliver ropes ready to match the exact mechanical and operational specifications of your crane model.

| Features of Tower Crane Steel Wire Rope

- High strength: Possesses high strength and can withstand significant tensile and compressive forces, ensuring the stability and safety of the crane.

- Lightweight: Lightweight construction for easy installation and maintenance.

- Good elasticity: Exhibits excellent elasticity to accommodate vibrations and impacts during lifting operations, reducing the risk of equipment damage.

- Versatility: Offers diverse structural and winding patterns to suit various application scenarios.

| Specification of Tower Crane Steel Wire Rope

| Type | Tower Crane Steel Wire Rope |

| Structure | 5×35 |

| Size | 12mm, 14mm, 16mm, 18mm |

| Packing | roll |

| Feature | High Strength. |

Why Choose My Hoisting Wire Rope?

I don’t just supply parts—I support performance. I’ve worked closely with crane operators, site managers, and maintenance teams to understand common rope failures and operational challenges. This insight drives my commitment to producing hoisting wire ropes that combine safety, strength, and serviceability.

- Consistent Stock Availability: Fast delivery for urgent replacements and project deadlines.

- Technical Support: Guidance on rope selection, maintenance intervals, and installation best practices.

- Factory Direct: Competitive pricing and full traceability from raw material to finished rope.

Tailored for Tower Crane Compatibility

Our hoisting wire ropes are compatible with major tower crane brands including Potain, Liebherr, Comansa, Zoomlion, and Terex. I can provide ropes cut to exact lengths and pre-fitted with end terminations or sockets, ready for installation, reducing your downtime on-site.

Quality Standards

Every batch of hoisting wire rope is manufactured in compliance with:

- ISO 4309: Rope discard criteria for cranes

- EN 12385: Safety requirements for wire ropes used in lifting

- DIN standards for rope construction and core type

We also provide load test reports, material certificates, and custom labeling upon request.

| Why Choose Us

As a customer-focused organization, CPTC offers a complete one-stop solution for construction projects. From product selection and procurement to installation and after-sales service, we provide comprehensive support throughout the project lifecycle. Our advantages are the following:

Trustworthy Performance

Backed by a fifteen-year reputation for excellence, CPTC spare parts deliver consistent and reliable performance, enhancing the overall efficiency of your operations.

Extensive Network

CPTC has established a strong network of reliable suppliers and distributors worldwide, guaranteeing you access to a wide range of crane parts and prompt service.

Customer-Centric Quality

Our rigorous quality control measures are driven by a steadfast commitment to delivering products that exceed customer expectations.

Peace of Mind

Rely on our one-stop service for hassle-free procurement, ensuring all your construction needs are met in one place.

Maximize Equipment Uptime with Comprehensive Support

Our after-sales package is designed to minimize downtime and optimize equipment performance.