Have you ever gazed at a building site and thought about how a crane manages to carry heavy concrete and steel with such grace? The answer boils down to one thing – a working arm, which is also known as a jib.

This post will describe what a working arm is, how it works, and explain its construction, as well as the reasons behind its size and angle, which are critical to safety and performance.

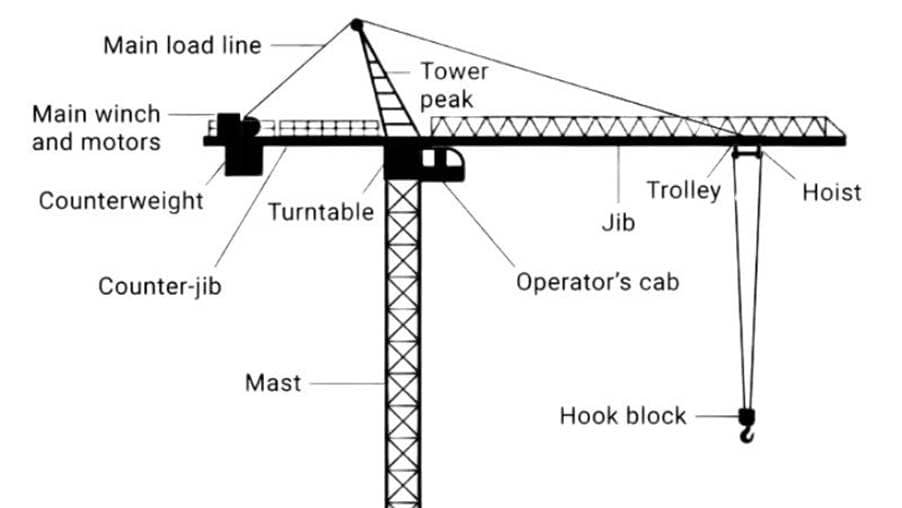

What Exactly Is the Working Arm?

The working arm is also called a jib. It is the long, horizontal section attached to the crane’s tower. It is responsible for all the lifting and moving activities.

Hoses are like an arm of a human body; they extend, grasp, and transport objects to designated areas. Without these hoses, a crane would be utterly useless in shifting heavy objects across a site.

What Does the Working Arm Do?

Moving a heavy load with precision is a task that the working arm can do quite effortlessly.

Here are the tasks that it is capable of doing:

- Using the hook and hoist system to lift the loads

- Using a trolley system to maneuver the loads across the site horizontally

- Positing the materials for builders to utilize it the correct way

In a broader sense, the working arm can give the crane its incredible finesse and range, which allows it to swing tirelessly across the skyline.

Main Parts of a Working Arm

To understand how it works, let’s look at what it’s made of:

| Component | What It Does |

| Main beam | The steel structure that supports the trolley and cables |

| Trolley | Moves back and forth along the beam, carrying the hook |

| Hook and hoist | Attaches to the load and lifts it up or down |

| Pulley system | Guides the wire rope and controls tension |

| Counter-jib | Sits on the opposite side to balance the working arm’s weight |

The components function in unison, as in a mechanical system, where every action elicits a reaction from other components to retain the equilibrium and lessen the sway of the crane, as would in a system of pulleys.

How Does the Working Arm Actually Work?

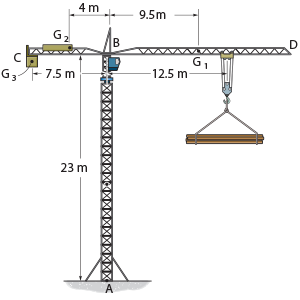

Just like anything in life, balance is key in lever systems.

The working arm of a crane is connected to a load, which exerts a downward force, or torque. This helps create a counter-jib and counterweight on the opposite side, which counterbalances the crane to keep it from tipping.

The operator moves the slewing mechanism from the tower which moves the trolley.

- Closer proximity to the tower increases lifting power.

- An increase in distance reduces lifting power but increases the reach.

Are All Tower Crane Arms the Same?

Not at all! Different projects require different types of working arms (jibs).

Here’s a quick comparison:

| Type of Jib | Key Features | Best For |

| Hammerhead jib | Fixed horizontal arm; trolley moves along it | High-rise buildings, open spaces |

| Luffing jib | Arm can tilt up and down | Tight urban sites with limited swing area |

| Flat-top jib | No top tie frame; easier to assemble | Projects with multiple cranes nearby |

More compact sites will often require use of a luffing jib crane; it’s one of the methods employed when space is particularly restricted.

How the working arm of a tower crane, Length and Angle,affects Lifting Capacity

The length and working angle of the jib directly affect how much weight the crane can lift safely.

| Jib Length | Max Load Capacity | Ideal Scenario |

| 30 m | ~10 tons | Small to medium construction sites |

| 50 m | ~6 tons | General high-rise projects |

| 60+ m | ~4–5 tons | Wide-open sites with long reach needs |

- Longer arm = more reach but less lifting power.

Every crane possesses a load chart which outlines the safe limits of the load being carried at various radii (distances from the tower). - Before performing any lifting, it is critical to review the chart, as even a minimal change in radius to a single meter could yield a drastic reduction in the safe carrying capacity of the crane.

Safety & Maintenance Tips

Due to the cumulative burden of heavy weight on the arm, every day it is imperative to check something for an inspection.

The following is a ready check list.

| Check Item | Why It Matters |

| Cracks or rust on the beam | Weakens structural strength |

| Cable and pulley wear | Affects lifting stability |

| Bolt tightness at joints | Prevents mechanical failure |

| Wind conditions | Strong winds can create dangerous sway |

This can also be said, “safety is the priority, not time: never let the crane burdon.”

Common Risks in Different Scenarios

| Work Scenario | Potential Risk | Safety Tip |

| Long jib in strong wind | Swaying and instability | Reduce load, operate at lower swing speed |

| Tight urban site | Collision with nearby structures | Use luffing jib and trained operator |

| Night operation | Low visibility | Ensure lighting and clear communication |

| Overreaching load | Crane tipping | Follow load chart strictly |

In Simple Terms

The horizontal arm of a tower crane isn’t simply a long piece of steel — it’s a carefully engineered mechanism that enables huge objects to be moved effortlessly and securely through the air.

It’s where might and accuracy intersect to aid in the ascension of today’s urban landscapes.

Related Products

Tower Crane Trolley

Multiple functions

Intuitive operation

Tower Crane Trolley Mechanism

Tower Crane Trolley Chassis

Withstands heavy loads and forces

Works with supporting…

Tower Crane Trolley Device

Multiple functions

Intuitive operation

Tower Crane Trolleying Limit Gear

Controls luffing motion

Improves safety and efficiency

Enables dynamic boom…