At any construction site, the vertical movement of personnel and materials is of vital importance. Construction hoists (also known as construction elevators) are the main equipment for achieving this goal, and their crucial role cannot be ignored. The performance of safety devices is directly related to the personal safety of construction workers. Once the downward running speed of the hoist cage exceeds the rated range, the anti-fall safety device will automatically start and use the braking device to steadily stop the hoist cage on the guide rail, thus effectively curbing the hoist cage falling accident.

This article delves deeply into the key issues that may endanger these devices, such as incorrect start-up speed and excessive braking distance, and provides practical solutions and maintenance procedures to ensure they operate as expected and safeguard life safety and project safety every day.

What is an Anti-Fall Safety Device and How Does It Work?

An anti-fall safety device is a mechanical unit installed on a construction hoist that automatically engages to stop and hold the hoist car in the event of an overspeed condition or a failure of the main hoisting system. Its primary purpose is to arrest a fall, not to be a routine braking mechanism.

Core Components & The Braking Principle:

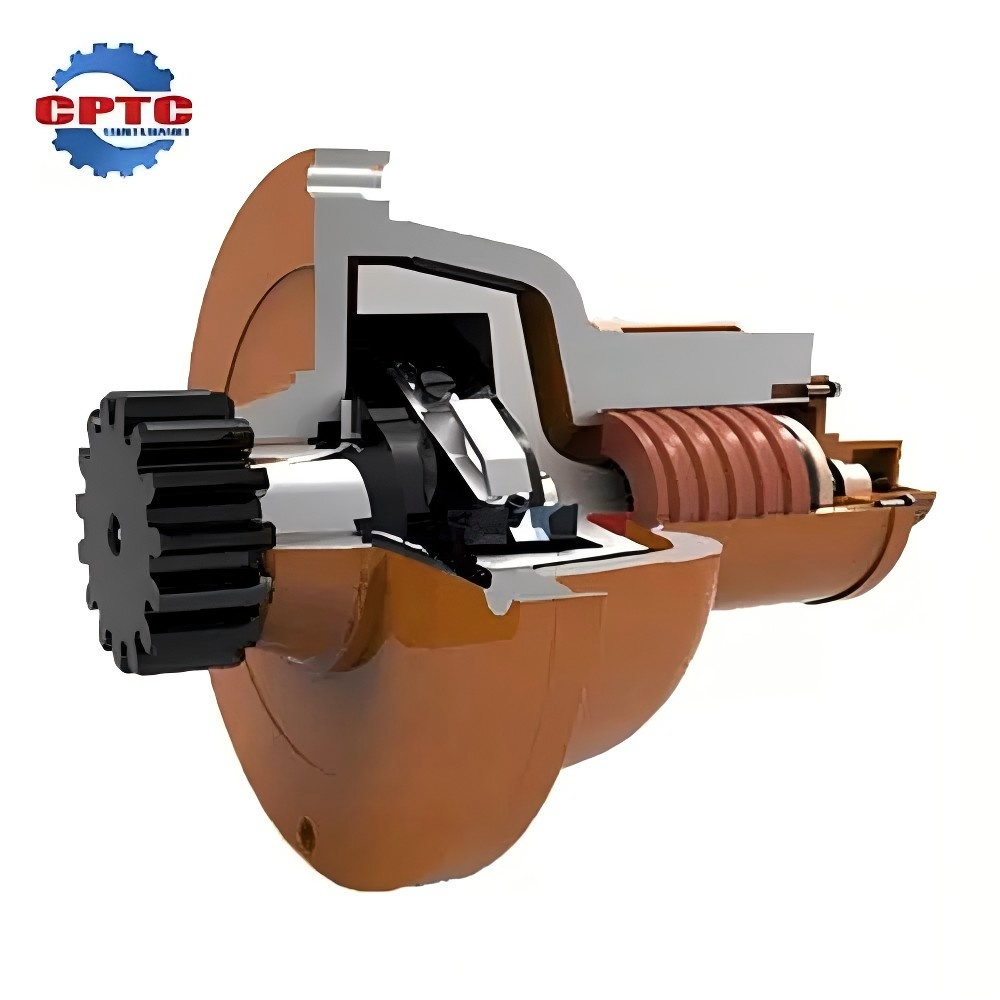

The most common type is a centrifugal, progressive safety device. Its core components include:

- Centrifugal Mechanism: Linked to the hoist’s guide rail or a dedicated governor rope, this mechanism spins at a speed proportional to the hoist car’s movement.

- Gears and Flyweights: As the hoist car descends, the mechanism spins. Centrifugal force causes flyweights to pivot outward.

- Locking Paws/Braking Elements: At a predetermined overspeed (typically 115-130% of the rated speed), the flyweights engage with locking paws or a trigger mechanism.

- Brake Shoes and Wedges: This engagement forces a set of brake shoes or wedges to clamp firmly onto the guide rails running the height of the structure.

The braking principle is one of positive mechanical engagement. The device converts the kinetic energy of the falling car into frictional heat energy through the clamping action on the guide rails, bringing the car to a controlled, gradual stop. It is a fail-safe system; its operation depends on physics, not external power.

Common Critical Issues & Practical Solutions

Identification of the typical failure modes of the devices is the beginning of prevention.

Incorrect Activation Speed

The Problem: The safety device picks up too early (a “nuisance trip”) or worse still, too late. Nuisance trips disrupt work and deliver jolts, while delayed activation means that the hoist will have too high a speed, potentially beyond the device’s designed stopping capacity.

Causes & Risks: The primary cause is improper calibration. Springs with time can fatigue, pivot points wear, and the centrifugal mechanism corrode or get dirty, all degrading its sensitivity. The risk is the dual failure: the primary system fails, and the backup system fails to activate at the correct speed, leading to a catastrophic event.

The Solution: Periodic testing and adjustment by trained technicians are not a choice. This involves using special equipment to simulate overspeed conditions and verifying that the device activates within the parameters established by the manufacturer and the regulator (e.g., ASME A10.4, ISO 4344). Never attempt any adjustment of the activation speed without training and proper equipment.

Too Great Braking Distance

The Issue: After the safety device trips, the hoist car travels for an unacceptably great distance before coming to a halt. A prolonged braking distance increases the risk of collision against the buffer or the shaft bottom.

Causes & Risks: It is most often caused by worn-out or dirty brake linings. Grease, oil, or dirt on guide rails or linings greatly reduces the coefficient of friction. Also, improper force by the braking system or worn-out guide rails could be the reason.

The Solution: Maintain a strict time line for the inspection and replacement of friction parts. During routine maintenance, there should be a check-up on brake linings’ thickness and replacements once they are reaching their wear limit. Guide rail cleanliness, alignment, and absence of deformations are equally critical.

High Braking Impact Force

The Problem: The machine stops the hoist too abruptly, subjecting passengers and loads to too high G-forces. This hurts individuals and it can also damage the contents of the hoist frame and the hoist frame itself.

Causes & Risks: Instant-type safety devices, which lock onto the rails instantly, are notorious for high impact forces. However, even progressive types can develop high impact if poorly maintained, mis-specified for the load, or if the guide rails are not well aligned.

The Solution: Best practice is to use progressive safety devices that are specially designed to create growing braking force gradually. Also, rating the device properly for the hoist capacity and application is needed. Load testing from time to time ensures that the braking force remains within desired limits for the intended application.

Insufficient Braking Torque

The Problem: The device is brought up but is unable to generate enough torque to restrain the hoist car when operating at its maximum rated capacity. This is a system failure.

Causes & Risks: It could be due to extremely contaminated or glazed friction surfaces, mechanical failure of the device itself (e.g., broken component), or, in the worst-case scenario, the device being underspecified for capacity and duty cycle of the hoist.

The Solution: Beyond keeping parts clean, annual load testing requirements are the last guarantee. This is done through the simulation of an overspeed condition with 125% of rated load upon the hoist to show that the device will engage and hold the car safely in place. Using units from reputable manufacturers and verifying they are certified for your specific model hoist is a minimum preventative step.

Maintenance and Repair of Anti-Fall Safety Devices

Preventive and proactive maintenance are the foundation of reliability. Reactive response—waiting for something to fail—is unsafe.

- Daily/Pre-Operation Inspection: Operators visually inspect the device for obvious signs of damage, oil leaks, or loose components. They verify that there are no guide rail obstructions.

- Scheduled Periodic Service: A qualified technician makes detailed inspections every month or quarter, depending on the manufacturer’s requirement. This includes:

- Washing the unit and checking for corrosion.

- Lubricating all points of movement with the correct lubricant.

- Checking for gear, flyweight, and brake lining wear.

- Torquing all bolts and fasteners to specifications.

- Third-Party Certification on an annual basis: The most vital service work is an annual inspection and test by a qualified, unbiased third party. This provides an unbiased verification of the device’s performance and ensures compliance with all local and global safety standards.

- Post-Trigger Action: If a safety device is tripped, the hoist must be taken out of service at once. The system—safety device, guide rails, and governor rope—must be thoroughly inspected by a qualified technician for damage before resetting the device and putting the hoist back into service.

All inspections, maintenance, and testing must be recorded in a full log, creating a record that can be verified of the equipment’s safety compliance.

Final Thoughts

The anti-fall safety device plays a crucial role in the rack and pinion transmission construction hoist and is a key device to ensure construction safety. By thoroughly analyzing the possible challenges it may encounter during use, we can better prevent potential problems and ensure the stable operation of the construction hoist.

FAQ

Q1: How often should a construction hoist anti-fall safety device be tested?

A: Regulations typically require a formal load test and inspection by a certified technician at least once every 12 months. However, visual checks should be done daily by operators, and more thorough inspections should be conducted monthly or quarterly as part of a preventive maintenance schedule.

Q2: What are the signs that my anti-fall safety device needs service?

A: Key signs include visible wear on brake linings, signs of oil or grease contamination on the device or guide rails, corrosion, unusual noises from the governor mechanism, and any history of nuisance triggering.

Q3: Can a safety device be reset after it’s been triggered?

A: Yes, but it must only be done by a qualified technician after a full inspection of the device, guide rails, and governor system to ensure no damage occurred during the activation. Never reset a triggered device and return the hoist to service without this inspection.

Q4: What is the difference between an instantaneous and a progressive safety device?

A: An instantaneous safety device locks onto the guide rail immediately, resulting in a very abrupt stop with high impact force. A progressive safety device applies the braking force gradually, bringing the car to a smoother, more controlled stop with significantly lower impact forces, making it the safer and more modern standard for personnel hoists.

Related Products

SRIBS Safety Device

The safety switch’s action is…

Construction Hoist Overload Indicator and Sensor

AC220V/50Hz

Overload Protection

High Capacity Relay

Compact Design

Durable Construction

Construction Hoist Gearbox and Parts

Trademark: CPTC, GJJ, PET, BAODA

Passenger…

Worm Wheel Shaft

Customized services;

With…