OEM CNC Machining Part

CPTC also offers CNC Making Product services, including Complex Parts Making by CNC and Mold Making by CNC. Rapid prototyping through CNC machining provides a high-speed, high-precision, and powerful rapid parts manufacturing solution.

Our company offers rapid prototyping and volume production services to customers across a diverse range of industries, including industrial automation, machinery, and manufacturing. We invite you to contact us with any questions regarding our products and services.

OEM CNC Machining Parts Based on Your Samples or Drawings

Looking for a reliable partner to bring your custom metal or plastic parts to life? I specialize in precision CNC machining parts tailored to your exact specifications. Whether you provide a detailed drawing or a physical sample, I turn your concept into high-quality, ready-to-use components with unmatched accuracy and consistency.

Mold Making by CNC

Mold manufacturing

High automation

Labor savings

Complex CNC Parts Fabrication

High efficiency

Versatility

Wide applications

Industries Served

- Automotive

- Aerospace

- Medical Devices

- Robotics

- Consumer Electronics

- Industrial Machinery

Custom CNC Machining Services Tailored to You

I understand that every industry and project has unique requirements. That’s why I offer OEM CNC machining services for various applications. I deliver consistent quality and tight tolerances from prototypes to large-volume production runs. Simply send your sample or technical drawing—I handle the rest with speed and precision.

What I Offer:

- CNC Milling & Turning

- Multi-Axis Machining

- Surface Finishing (Anodizing, Sandblasting, Powder Coating, etc.)

- Tight Tolerance Capability (±0.01mm)

- Support for Aluminum, Stainless Steel, Brass, POM, and more

From Concept to Final Part

Have a sketch or just a prototype? No problem. I analyze your sample or drawing and recommend the most efficient machining approach. My experienced engineering team supports material selection, tolerance review, and production planning to ensure the end part meets your technical and functional goals.

| Benefits of CNC Making Product

- Customized Services: We offer a wide range of surface treatments tailored to solid metal and plastic components, ensuring precise adherence to design specifications.

- Rapid Prototyping: CNC machining’s versatility across a diverse range of materials makes it ideal for rapid prototyping, including the creation of jigs and molds.

- Quality Control: Our quality assurance department meticulously implements stringent quality control procedures.

Why Work With Me?

- Fast Turnaround: Rapid prototyping and on-time batch delivery.

- Strict Quality Control: Every part goes through multiple inspections—dimensional, surface, and functional.

- Material Versatility: I work with metals and plastics commonly used in demanding environments.

- One-on-One Support: Direct communication from quotation to delivery. I make sure your part is done right.

File Formats Accepted:

- STEP / IGES / STL / DWG / PDF

- STEP / IGES / STL / DWG / PDF

- Or simply send a physical part—I’ll reverse-engineer it.

MOQ & Lead Time:

- No minimum order required. Typical lead times range from 3–7 days for prototyping, 7–15 days for volume production, depending on complexity.

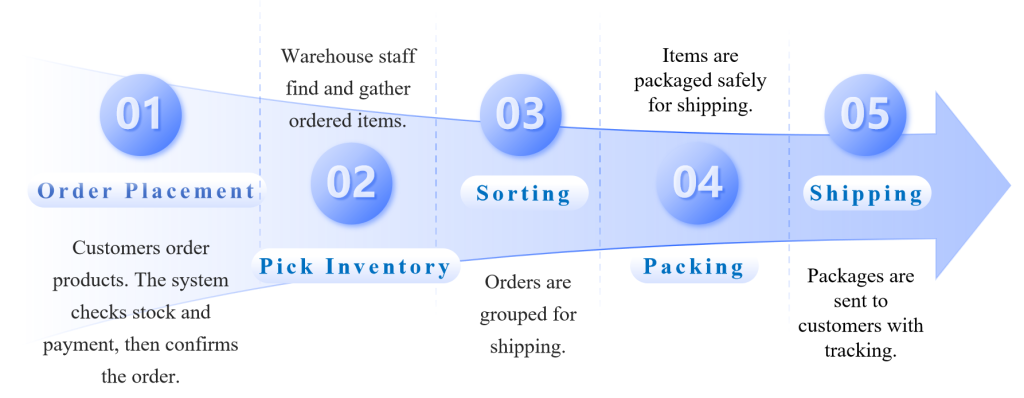

| Ordering Process

| Packing & Delivery