The electric suspended platform, an indispensable tool in construction projects, has become a powerful assistant in the field of high-altitude operations due to its high efficiency and convenience. Among the various types of suspended platforms in the market, the ZLP series suspended platform stands out and has become one of the most popular and standardized models worldwide. In this article, we provide a clear and actionable breakdown of the ZLP series specifications, a key safety checklist, and a detailed cost analysis to help you choose the right model.

Understanding the ZLP Suspended Platform System

A ZLP suspended platform is a temporary suspended access system used for carrying workers, tools, and materials during construction and maintenance of tall buildings.

It is powered by electric motors and suspended by steel wire ropes from the top of the building. The platform can be raised or lowered vertically along the façade using a lifting mechanism controlled by operators on the platform itself.

What Does “ZLP” Mean?

The “ZLP” designation is a Chinese industry standard code used to identify suspended working platforms that meet GB19155 and EN1808 safety requirements.

“Z” stands for “Zuo Ye” (working),

“L” for “Liu Dong” (mobile or suspended), and

“P” indicates “Platform.”

In short, ZLP = Mobile Working Platform.

ZLP models are widely produced by rope suspended platform manufacturers in China, known for offering reliable performance and excellent cost-effectiveness compared to Western brands.

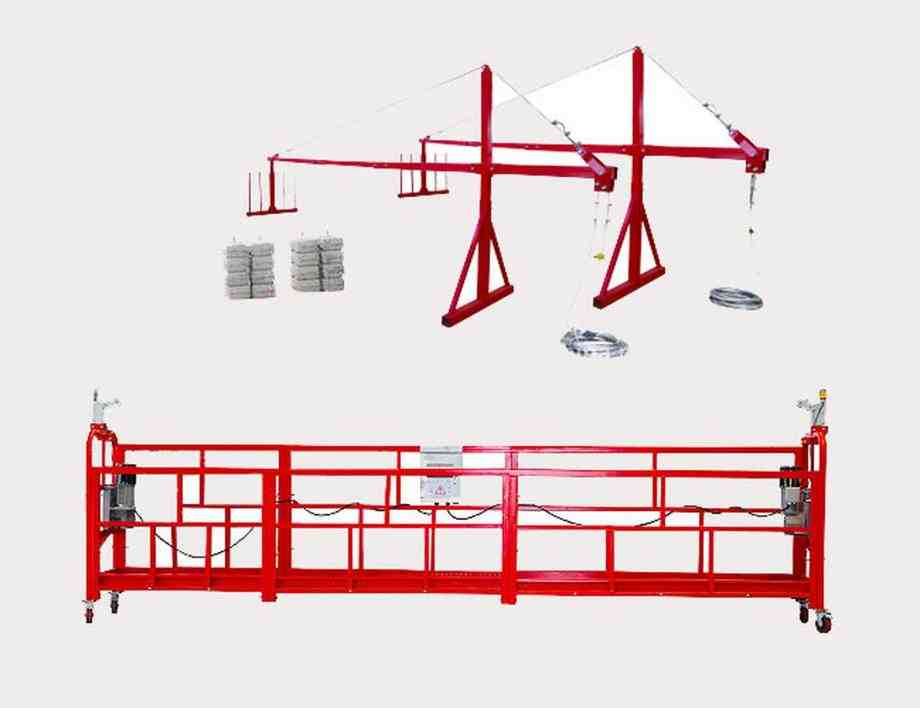

Main Components of a ZLP Suspended Platform

A complete ZLP rope suspended platform system typically consists of the following parts:

- Suspended Platform (Working Platform): The aluminum or steel basket where workers stand and operate. Common lengths range from 2m to 8m.

- Hoist (Lifting Mechanism): The heart of the system, usually an electric hoist that moves the platform up and down via wire ropes. Popular models include LTD6.3 and LTD8.0.

- Safety Lock: An automatic fall arrest device that instantly locks the steel rope if the platform tilts or descends too quickly.

- Suspension Mechanism (Roof Rig): Installed on the rooftop or structure top, it supports the steel ropes and allows safe suspension of the platform.

- Electrical Control System: Includes the power distribution box, control buttons, and emergency stop for operating the platform safely.

- Steel Wire Rope and Safety Rope: The working rope bears the load, while the safety rope provides redundancy for worker protection.

- Counterweights and Cable System: Counterweights ensure stability, and cables supply power to the hoists.

Each component must comply with safety standards and be maintained regularly to ensure smooth operation.

ZLP Models and Load Capacity Selection

Selecting the correct ZLP model hinges entirely on your project’s needs—specifically, the maximum required payload and the nature of the work.

| Model | Rated Load | Platform Length | Hoist Type | Rated Speed |

| ZLP630 | 630 kg | 6 m | LTD6.3 | 9–11 m/min |

| ZLP800 | 800 kg | 7.5 m | LTD8.0 | 8–10 m/min |

| ZLP1000 | 1000 kg | 7.5 m | LTD10.0 | 8–10 m/min |

Three Key Factors When Choosing a Model

- Job Scope (Light vs. Heavy Duty): If your project involves installing heavy glass panels or thick insulation boards, the ZLP800 is necessary to handle the weight of materials, tools, and the crew. Using a ZLP630 for an 800kg job is a recipe for hoist burnout and a major safety violation.

- Platform Length: While ZLP platforms are modular, ensure the chosen configuration fits the architectural contours of the building. Longer platforms require greater structural integrity and must be perfectly balanced by the suspension system.

- Hoist Power and Control System: Reliable electric hoists with smooth start-stop functions reduce jerking and improve worker comfort. Look for certified LTD series hoists with CE or ISO approval.

Six Common Traps When Buying or Renting Suspended Platforms

Whether you choose to buy or rent, the following pitfalls are where companies most often sacrifice quality for price, leading to hidden costs down the line.

Buying Traps:

- Pitfall 1: Cheap Hoists with Zero Warranty. The manufacturer may use a standard ZLP sticker but install a motor with a low MTBF (Mean Time Between Failures). Insist on brand-name hoists or certified, third-party audited motors. Downtime from hoist failure can cost thousands per day.

- Pitfall 2: Inferior Wire Rope and Electrical Cable. Look closely at the steel cable’s diameter and core material. Low-quality wire rope frays quickly, necessitating frequent and costly replacements. Similarly, cheap electrical cables degrade faster, leading to intermittent power faults.

- Pitfall 3: Subpar Suspension Rigging Steel. The rigging is often painted over to hide poor quality. Insist on documentation proving the steel thickness and grade (e.g., Q235 or higher) and verifying that the structure has been properly load-tested to meet the $3:1$ safety factor.

Renting Traps:

Pitfall 4: Untraceable Recertification Records. Renting older equipment is common. Always demand to see the current certification documents, especially the inspection records for the Safety Lock and the last comprehensive check, ensuring compliance with OSHA or EN 1808 standards.

Pitfall 5: Hidden Fees and Contract Traps. Rental quotes often omit necessary costs. Clarify who is responsible for: Transportation Fees, Onsite Installation/Dismantling Labor, and Daily Standby Rates (when the platform is idle due to weather or other delays).

Pitfall 6: Inadequate Counterweights. The supplier must provide certified Cast Iron or High-Density Cement Weights that meet the required counterweight ratio. Never accept uncertified or makeshift weights, as this is a fundamental safety breach.

Cost and Price Range Analysis

The cost of a ZLP electric suspended platform depends on model, material, hoist brand, and configuration:

| Model | Material | Approx. Price (Factory) | Rental Price (Monthly, China) |

| ZLP630 | Steel | $800–$1,200 | $100–$150 |

| ZLP800 | Aluminum | $1,200–$1,800 | $150–$200 |

| ZLP1000 | Aluminum | $1,800–$2,500 | $200–$250 |

Additional costs may include:

- Spare wire ropes and locks

- Transportation and customs

- On-site installation and training

To reduce risk, always ask for a factory test video, quality certificate, and warranty terms before making a purchase or rental decision.

Building Higher with Confidence and Safety

The ZLP electric suspended platform is not merely a construction tool; it is a safety-critical system that directly affects the lives of workers and the efficiency of the project.

When purchasing or renting, do not only look at the price: give priority to certified quality, reliable elevators and strong after-sales service. By understanding the structure, models and selection criteria of the ZLP series, you can make wiser decisions, avoid costly mistakes and ensure the safety of your workers at any level.

Related Products

Construction Platform

With a lightweight…

Hoist Gearbox

Stable and reliable operation, secure

High flexibility, adjustable speed

Wide range…

Rope Presser

Wire rope protection

Strengthens wire rope

Improves safety…

Sheave Assembly

Effortless and efficient

Advanced design and manufacturing technology

Multiple…