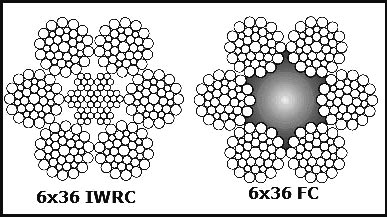

Ever wonder what type of wire rope is suited for a crane or a hoist between IWRC and FC?

You are far from alone — this is amongst the most asked questions in the lifting and rigging industry.

- IWRC (Independent Wire Rope Core) = deals with crushing and heat better. More stronger and tougher.

- FC (Fiber Core) = Smoother to handle, Less flexible and stronger.

Ideas and concepts will be illustrated in this analysis with real-world comparisons and practical options to assist you in understanding what is most suited for your needs.

What Is the Difference Between IWRC Wire Rope and FC?

| Machine / Application | Recommended Type | Reason |

| Tower crane / offshore rig | IWRC | High strength, crush & heat resistance |

| Winch drum (multi-layer) | IWRC | Maintains shape, longer life |

| Elevator / small lift | FC | Smooth, flexible, quiet |

| Mobile crane | FC | Frequent bending, lighter handling |

| High-temp environment | IWRC | Fiber core may dry out |

| Pulley with tight radius | FC | Soft, easy bending |

- Static and heavy loads are classified as IWRC which means Inner Wire Rope Core.

- Also, bending and smooth movement of cables are classified as FC or Flat cables.

Any type of decision must be understood on its peculiarities such as how it functions as well as its effectiveness.

IWRC = Independent Wire Rope Core (Built for Strength)

What It Is

IWRC, or ‘Inner Wire Rope Cor,e’ is the ability of the core to be a small steel wire rope within the circumference of the main rope

This gives the rope additional support. It also allows the rope to carry heavier loads without undergoing plastic deformation.

Core Function

The rope remains circular, and while the core shares the weight, its steel center, most importantly, prevents crushing under pressure, especially when wound on a drum in multiple layers.

Advantages

- Increased tensile strength — can support larger loads.

- Improved crush resistance — won’t collapse as easily.

- Increased heat resistance — can withstand hot temp changes.

- Improved durability whilst performing heavy-duty operations.

Limitations

- Less flexible – more rigid when bending around smaller pulleys

- Greater weight – more effort required to handle manually

- Slightly greater price

Best Applications

- Lifting towers

- Construction lifting with layered winches

- Lifting devices for use at sea

- Extractive and civil engineering industries

Why IWRC Is Stronger

Due to the tension, both the core and outer strands, which are both steel, equally share the load. So when extreme force is applied, the rope remains rounded, more stable, and less easily crushed compared to other ropes.

FC = Fiber Core (Built for Flexibility)

What It Is

A fiber core (FC) can consist of natural fibers like sisal or hemp as well as synthetic fibers like polypropylene.

FC serves as padding and facilitates smoother flexing and movement.

Advantages

- Flexible and Resilient: Great for Frequent Bending

- Easy Mobility: Lightweight and Effortless to Install

- Reduced Wear: Retains Lubrication and Lessens Inner Wire Deterioration

- Reduced Wear: More Economical for General Utility Purposes

Limitations

- Reduced breaking strength

- Poor resistance to crushing under extreme pressure

- Lack of resistance to elevated temperatures — fiber will dry or deteriorate

- Reduced operational lifetime under extreme environments

Best Applications

- Elevator

- Katrol ringan

- Crane bergerak

- Sistem pulley dengan gerakan frekuent

Why FC Is More Flexible

Pusat yang empuk memijat serat lembut saat helai-helai baja melonggar akibat tekukan tali.

Karena ini, tali FC berfungsi pada pengaturan katrol yang konstan dan pada penggulungan yang konstan.

IWRC vs FC:Parameter Comparison

| Performance Parameter | IWRC (Steel Core) | FC (Fiber Core) |

| Tensile Strength | Very High | Medium |

| Flexibility | Moderate | Very High |

| Heat Resistance | Excellent | Weak |

| Crush Resistance | Excellent | Poor |

| Corrosion Resistance | Good (if galvanized) | Good (with lubrication) |

| Weight | Heavier | Lighter |

| Cost | Slightly higher | Lower |

| Service Life (under heavy load) | Longer | Shorter |

| Best For | Heavy lifting & high pressure | Frequent bending & lighter loads |

IWRC vs FC: How to Choose the Right One

read more:What type of wire rope is used on cranes?

Memilih tali kawat. Bergantung pada jenis muatan yang akan diangkat, frekuensi pembengkokan tali kawat, dan kondisi kerja.

Inilah cara para spesialis membuat keputusan.

Check your load

- High, constant tension → IWRC

- Repetitive or flexible movement → FC

Look at the pulley or drum size:

- Small pulleys → FC

- Large or multi-layer drums → IWRC

Consider the environment:

- High heat or heavy pressure → IWRC

- Normal indoor work → FC

Think long-term:

- IWRC = lasts longer, higher cost

- FC = easier to replace, lower cost

Pro tip: Always follow your machine manufacturer’s rope specifications — wrong core type = premature wear or rope failure.

Common Misconceptions & Safety Notes

| Myth | Reality |

| “IWRC is always better.” | Not necessarily — FC is better for flexibility and frequent motion. |

| “FC ropes can’t lift heavy loads.” | They can, within rated limits. |

| “You can replace FC with IWRC anytime.” | Wrong — groove shape and machine design matter. |

| “Fiber core ropes are outdated.” | Still widely used for elevators and small cranes. |

| “All ropes perform the same under heat.” | FC can degrade quickly in hot conditions; IWRC holds up better. |

Safety reminder: Never overload a rope beyond its rated capacity — and always inspect both core and strands for damage before use.

Summary

IWRC = Strength, FC = Flexibility

| If You Need… | Choose… |

| Maximum strength & durability | IWRC |

| Smooth bending & easy handling | FC |

| High temperature or heavy pressure use | IWRC |

| Light-duty or frequent bending jobs | FC |

- IWRC stands for power, structure, and long life.

- FC stands for flexibility, ease, and motion control.

Related Products

Construction Hoist Cable

Durable Protection

CE Certified

SGS Guaranteed

Safety Rope

Lightweight and Portable

Durable and Long-lasting

Wire Rope

High Tensile Strength and Durability

Compliance with Safety…

Rope Presser

Wire rope protection

Strengthens wire rope

Improves safety…