In the case of lifting and hoisting operations, all crane components, especially the hoist and sheaves, play a vital role in load handling. Crane components have to be manufactured with precision engineering, They have to be precise, trustworthy and useful. It’s common that pulleys are neglected, but in fact, every kind of crane like a tower crane, bridge crane, and even mobile cranes rely heavily on their sheaves to control the movement of steel wire ropes and the efficient handling of the load.

In the case of procurement, supply and in some cases even design of cranes and their components, understanding the parts of the system that are working in tandem and their working principles is imperative. In this article, we will delve a little deeper and discuss the use, maintenance, and most common types of crane sheaves.

What Is a Crane Sheave?

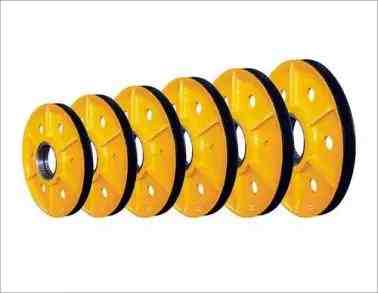

A crane sheave is a type of lifting device. It is a wheel or ground pulley that is operated on a shaft or axle. its purpose is to guide a wire rope or cable, aid in its free movement in all direction while minimial friction, wire rope, to move “freely in all accrued directions.”. sheaves are often housed within a crane’s boom, jib or hook block. in the sheave, the groove is the most important part because it cradles the wire rope so it is in the correct position and will not slip off while ensuring its shape and integrity, especially under immense levels of tension.

With the purpose of the sheave in mind, its main purpose is to aid in relieving crane lift cases of sheave and lifting motor load . The efficiency of the crane is aided or altered dependent on the wire ropes and sheaves. The lifting power of the crane is not the only aspect altered, all circuits are aided to have a greater efficiency when a greater number of sheaves and wire ropes are present.

What Are Sheaves on a Crane Used For?

The functions of a crane sheave are assisting in lifting operations. Let’s analyze a few of their pivotal functions.

- Force Multiplication and Mechanical Advantage: To provide a mechanical advantage is the most pivotal function of sheaves. The wire rope is reeved through numerous sheaves in the hook block and the boom tip. This configuration enables the lifting force to leverage numerous lines of rope. The block and tackle system is the name given to this configuration. The crane’s lifting capacity is enhanced through this system. A classic example is a two-sheave system. A two-sheave configuration gives an advantage of about fifty percent to the lifting force, ofcourse excluding frictional losses.

- Directional change of wire rope: For the movement of the wire rope from the hoist drum to the boom and from there to the hook block, sheaves wire Directional Change. They ensure that the rope change direction in the crane’s body that it smooth and therefore does not get worn out.

- Reduction of Friction and Wear: A well maintained and correctly designed sheave will have a marked reduction of friction due to the sheave rotating freely on its bearing as the wire rope moves. This improves the efficiency of the lifting process and prolongs the operational life of the costly wire rope since less heat and abrasion is being generated.

- Load Distribution and Stability: Sheaves also aid in the balanced and stable lift by distributing the load and therefore increasing the number of rope lines. This is especially critical during the handling of large and bulky loads where control is very important for safety.

Common Types of Crane Sheaves

Crane sheaves are manufactured from a variety of materials and come in several designs to suit different applications, load capacities, and environmental conditions. The choice of sheave type directly impacts the performance, longevity, and safety of the crane.

| Sheave Type | Material | Common Use Case | Key Features |

| Tower Crane Sheave | Forged steel | High-rise construction cranes | Heavy-duty, high-load resistance |

| Overhead Crane Sheave | Cast iron or steel | Factories, warehouses | Moderate loads, smooth operation |

| Mobile Crane Sheave | Steel or alloy | Mobile lifting equipment | Lightweight, durable |

| Nylon-Coated Sheave | Steel + Nylon cover | Indoor or low-noise environments | Reduced noise, protects wire rope |

| Custom Machined Sheave | Customer-specified | Special machinery, OEM applications | Tailored dimensions and groove design |

How to Choose the Right Crane Sheave?

Choosing the right crane sheave for your crane is an important decision that requires careful consideration. Optimal performance, safety, and durability of the sheave and wire rope must be prioritized.

- Load Capacity: The sheave you choose should be able to handle the crane’s maximum load. The load is expected to carry along a dynamic safety factor and other unforeseen stresses.

- Wire Rope Diameter and Construction: The sheave groove must not be a smaller neither larger than the wire rope diameter. If it is smaller, it could inflict damage by pinching the rope. A larger groove will not provide needed support leading to flattening and excessive wear. Lastly, the groove’s outfitting should parallel the construction of the wire rope.

- Operating Speed: Sheaves equipped with roller bearings should be used for high-speed hoisting, as they do not allow overheating and excessive wear to happen.

- Environmental Conditions: Corrosive environments, marine and chemical plants, requires the use of sheaves made from corrosion resistant materials like stainless steel or nylon.

- Duty Cycle: The operational frequency and workload of the crane will dictate the selection of the sheave. Continuous heavy operational duty will need sheaves with better bearings; these will differ from the light duty, intermittent applications which are easier to manage.

- Bearing Type: The factors which differentiate the selection of bronze bushings and roller bearings include the load and speed, and how easily these factors can be maintained. Although roller bearings are more prone to contamination, they do provide decreased friction.

Maintenance Tips for Crane Sheave

Regular and thorough maintenance of crane sheaves is critical for appropriate personnel safety and for maximizing the operational life of the equipment. Catastrophic failures are likely to happen when proper sheave maintenance is neglected.

Regular Inspection Summary:

- Groove Wear: Always check the sheave grooves contour and diameter using a sheave gauge. Corrugated or worn grooves will cause severe damage to the wire rope.

- Flange Wear: Visually assess the sheave flanges for any cracks, chips, and excessive wear. A broken flange would cause the wire rope to jaundice the sheave.

- Bearing Health: Check for any unusual noise such as grinding or squealing, as this would indicate a failing bearing. Examine the sheave for any wobble or excessive play as this is an indicator of bearing wear.

- Lubrication: Check to see that the sheave bearings are properly lubricated as per the instructions of the manufacturer. Lubrication is critical to minimize operational friction and the risk of failure. For sealed bearings, look for any signs of grease leakage.

- Free Rotation: When the crane is locked and tagged, rotate the sheave manually and check that it rotates freely and does not bind.

- Alignment: Check the alignment of the sheave with the wire rope, to ensure that there is no disproportionate wearing of the sheave flange and the rope.

Proactive Maintenance:

- Cleaning: Regularly remove any dirt and debris, grease and grease build up from the sheave, as it could attract finely abrasive particles and make inspections more difficult.

- Record Keeping: Create and maintain all logs of inspections, maintenance performed, issues observed, and any actions taken. This log helps in analyzing repetitive faults and planning replacements in advance.

- Timely Replacement: Always be ready to remove and replace a sheave that is visibly worn or damaged. The sheave’s replacement cost is minimal when compared to the potential cost of a wire rope failure or a major accident.

CPTC: High-Quality Crane Sheave Assembly Supplier

CPTC fulfills diverse sheave requirements for different categories of cranes. Their sheaves, forged from advanced materials and innovative manufacturing techniques, guarantee reliable performance through lifting and heavy loads. CPTC also boosts the operational safety and efficiency of your lifting processes by providing standard sheaves, specially designed for replacement, or bespoke tailored components.

You are invited to reach out to CPTC for comprehensive instructions for tailored estimation to ensure that your crane functions safely and reliably.

Related Products

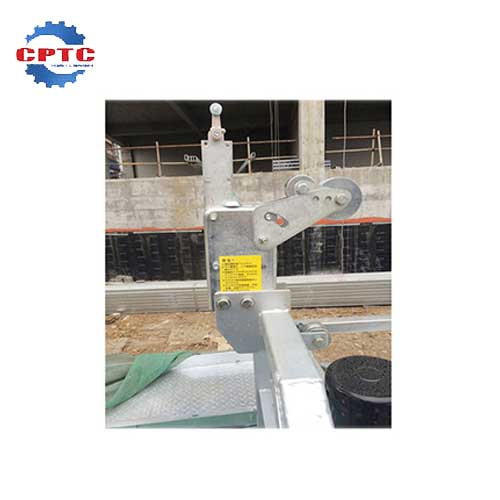

ZLP Series Suspended Platform

Simple and quick installation

Multiple security measures

Stable and…

Suspended Platform Safety Lock

Easy to Operate and Use

Made…

Construction Platform

With a lightweight…

Limit Switch

Compact and Lightweight

Easy Installation