At any large construction site, hoisting heavy objects and safely moving workers between floors are of Paramount importance. Construction hoists are precisely designed for this purpose. But not all elevators have the same structure. As modern projects become increasingly complex and time-pressured, traditional lifting systems often fall short in terms of efficiency and operational stability.

The SC series variable frequency hoist is one of the most favored solutions in the industry. This series of elevators is designed to achieve better control, higher energy efficiency and greater safety, and is becoming the preferred choice for construction sites around the world. But what on earth is it? How does it work? Let’s find out.

What Is an SC Series Frequency Conversion Hoist?

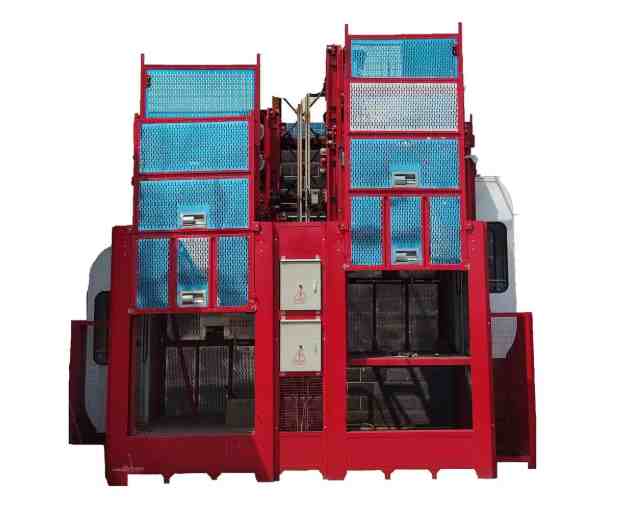

The SC series rack and pinion construction hoist is a typical rack and pinion construction hoist, widely used for vertical transportation of humans and goods in construction. “SC” stands for “single cage” or “Double cage” (depending on the model), and it typically comes with digital displays, e.g., SC200/200, indicating that one cage can carry a load of 2000 kilograms.

The characteristic of this kind of elevator is that it adopts frequency conversion technology to provide variable speed control. This sort of system replaces the traditional constant-speed motor with a sudden start-stop property, enabling the lift to accelerate and decelerate in a smooth manner. As a result, it reduces mechanical stress and enhances the comfort of in-building operators.

This type of elevator is normally fixed in tall buildings, Bridges, power stations and large-size infrastructure projects. Whether it is lifting steel beams, brick pallets or a group of workers, variable frequency elevators can provide more precise performance compared to normal elevators.

How Does Frequency Conversion Work?

The Variable Frequency Drive (VFD) is the heart of an SC series frequency conversion hoist. To understand its functionality, let’s examine the basics of an electric motor. Most industrial motors, and construction hoists included, are AC induction motors, and their speed is proportional to the power source frequency.

Traditional hoists power the motor straight from the supply power, often through a chain of contactors that switch between a group of winding schemes to implement limited steps of speed (high and low speed, for example). This creates sudden braking and acceleration, increased wear and tear, and elevated acceleration power consumption.

A frequency converter, on the other hand, works on the basis of taking the input fixed-frequency AC power (say, 50 Hz or 60 Hz) and converting the same to variable-frequency, variable-voltage AC output. Following is a step-by-step general description of the process:

1. Rectification: The input AC power is first converted to DC power by a rectifier.

2. DC Bus: The DC power is stored in a DC bus, usually filtered using capacitors.

3. Inversion: An inverter section then converts the DC power back to AC power, but with the difference that it can now precisely control both the output voltage and frequency.

With a continuous variation of the voltage and frequency fed into the hoist motor, the VFD can supply precise control of the speed of the motor from zero right up to its peak rated speed, and even above in some cases. This “stepless” acceleration and deceleration is credited with smooth acceleration and deceleration, leading to a more controlled and safer drive, reduced mechanical stress on the hoist equipment, and significant saving of energy. The VFD also facilitates regenerative braking, where the energy generated during deceleration can be fed back into the power grid, further enhancing the energy economy.

Top Features and Why They Matter on Site

Adding frequency conversion technology brings with it a plethora of features that are highly beneficial on site.

- Smooth and Stable Movement: Perhaps the greatest advantage. The smooth accelerating and decelerating eliminate jerking starts and stops common to standard hoists. Not only is this a smoother ride for manpower, but it also reduces swaying of materials, making loading and unloading safer and simpler. It also lessens mechanical shock and vibration on the structure and components of the hoist significantly.

- Enhanced Safety: Precise speed control allows for higher-quality braking at accurate floor levels, without overshooting or undershooting. Besides, the VFD generally comes with the best braking systems and fault detection, which cause the hoist to stop immediately in case of an anomaly. Smooth movement also reduces the likelihood of mechanical failure due to stress.

- Energy Efficiency: Frequency conversion hoists are very energy-efficient. Through precise matching of motor speed to the load requirement and supply of regenerative braking, they consume a lot less power than fixed-speed hoists, especially during starting and stopping motions. This translates directly to reduced operating costs over the life of the project.

- Reduced Mechanical Wear and Tear: Elimination of jolting and stresses on the motor, gears, brakes, and other mechanical components prolongs the life of hoist parts. This lowers maintenance costs and downtime for maintenance operations, improving overall productivity.

- Increased Comfort and Productivity: For employees, the comfortable ride reduces fatigue and instills confidence, which contributes to a more productive work environment. For materials handling, the cage’s stability prevents damage to delicate material and allows for quicker and safer loading and unloading.

Typical specifications and configurations

One of the most common models on the market is SC200/200, which is equipped with two cages, each with a load capacity of 2,000 kilograms. According to on-site requirements, the lifting height of these hoists can reach over 150 meters, and the lifting speed is adjustable. Under normal circumstances, the lifting speed ranges from 0 to 63 meters per minute.

Other notable specifications include:

- Motor power: Generally, depending on the configuration, the power of each hoist cage ranges from 2×11 kilowatts to 3×15 kilowatts.

- Mast section: Modular, expandable, pin connection, welded steel structure.·

- Cage size: Apers. 3.2 meters (length) × 1.5 meters (width) × 2.2 meters (height)

- Safety system: Emergency stop button, interlock device, limit switch and fall protection device

CPTC is a leader in providing custom-configured lifts. If contractors need to wholesale purchase Chinese construction lift equipment based on specific project requirements, they can contact us.

Applications in the Construction Industry

The adaptability and efficiency of SC series frequency conversion hoists render them definite essentials in a wide range of construction applications:

- High-Rise Building Construction: This is most likely their most frequent application. In the case of residential towers, commercial high-rises, and mixed-use developments, these hoists efficiently transfer people, concrete, steel, rebar, façade units, and interior finishing modules to every story. Their quick lifting speeds and safety features are particularly beneficial here.

- Bridges and Dam Construction: On mega infrastructure, hoists are used for transferring workers and materials to upper levels, towers, or into the confined spaces of dam structures.

- Power Plant Construction: For thermal, nuclear, or hydroelectric power plants, their construction at times involves the use of enormous structures and the need to raise heavy units. Frequency conversion hoists are suitable in such harsh conditions.

- Chimney and Cooling Tower Construction: Access to extremely high levels safely and productively is most important for these specialty structures.

- Overhaul and Refurbishment Projects: Even for old structures being fully revamped, hoists provide necessary vertical access for material supply and waste removal.

- Industrial Plants: Factory construction or warehouse expansion and industrial plant extension also finds the safe and productive lifting capability of these hoists beneficial.

In essence, any building construction project that requires regular and secure vertical conveyance of materials and people will benefit significantly from an SC series frequency conversion hoist.

Wrap Up

If your building site needs safe, efficient, and reliable vertical transportation, the SC Series frequency conversion hoist is an investment that’s well worth making. From smoother performance to reduced maintenance requirements, it has a great deal to bring to the table over normal models. With options like the SC200 construction hoist on sale everywhere and adjustable through China wholesale construction hoist suppliers, the price of upgrading your lifting gear has never been better.

As construction continues, so must the gear you rely on. Investing in the most recent lifting technology in the form of frequency conversion hoists isn’t about keeping up—it’s about getting ahead.

Related Products

GJJ Construction Site Hoist

With a lightweight…

SC Series Frequency Conversion Hoist

Frequency conversion control system.

Smooth starting and braking, less mechanical…

Construction Material Hoist

Use high-quality steel

Simple and cost-saving

Builder Hoist Lift

Flexible

Multifunctional

Easy to operate