Tower cranes, as indispensable heavy equipment on construction sites, their efficient and stable working conditions cannot do without the support of key components, among which the slewing bearing is a crucial component. This component is also known as the slewing ring, which enables the upper structure of the tower crane to rotate smoothly while bearing huge loads.

Without slewing bearings, tower cranes would not be able to rotate 360 degrees and thus precisely transport materials on construction sites. In this article, we will answer key questions about the slewing bearings of tower cranes, including their definition, main functions, typical sizes, types, and how to choose the right bearing for your project.

What Is a Slewing Bearing on a Tower Crane?

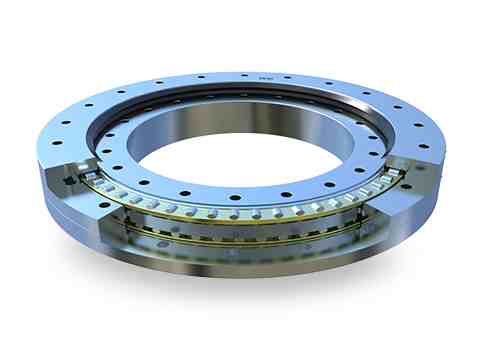

The slewing bearing (or slewing ring) of a tower crane is a large bearing capable of withstanding combined loads. It is installed between the tower body and the boom of a tower crane, serving to connect and support, allowing the boom to rotate freely at 360 degrees. This type of bearing is usually composed of inner and outer rings, rolling elements and other parts, featuring high load-carrying capacity and good rotational flexibility, ensuring the stability and high efficiency of tower cranes during operation.

The structural design of slewing bearings is highly precise, typically composed of multiple rows of rollers and raceways, capable of withstanding complex loads from all directions, including radial, axial, and overturning moments, etc. This design enables the slewing bearing to maintain extremely high stability and durability when supporting the rotation of the boom. In addition, the slewing bearing also adopts a sealing and lubrication system to ensure that it can work normally for a long time even in harsh construction site environments.

In short, the slewing bearing acts as the “rotary joint” of the crane, ensuring that the upper part of the crane can rotate stably and controllably even under heavy load conditions.

Main Functions of a Tower Crane Slewing Bearing

During the operation of tower cranes, slewing bearings play a crucial role. It not only supports the entire weight of the boom but also bears various complex loads generated by the lifted weight.

- 360° rotation – It enables the upper structure of the crane to rotate continuously, thereby enhancing the flexibility of the crane during lifting operations.

- Load-bearing capacity – It supports the vertical weight of the crane structure, the lifted load and counterweight.

- Bending moment resistance – It can withstand tilting moments caused by unevenness or heavy loads, ensuring stability.

- Smooth and precise movement – By minimizing friction, it enables the crane to rotate precisely, thereby achieving accurate load positioning.

- Structural connection – It links the upper structure of the crane to the mast, making it a crucial connection point in the entire system.

Therefore, the performance of slewing bearings directly affects the working efficiency and safety of tower cranes. It can be said that without slewing bearings, tower cranes cannot rotate safely and efficiently.

What Sizes Are Tower Crane Slewing Bearings?

Slewing bearings for tower cranes come in different sizes depending on the crane’s lifting capacity, working radius, and application. The diameter typically ranges from 1 meter to over 4 meters.

Here’s an overview of common size ranges:

| Tower Crane Capacity | Typical Slewing Bearing Diameter | Load Capacity (Approx.) |

| Small Tower Cranes (4–8 tons) | 1.2 m – 2.0 m | Light to Medium Loads |

| Medium Tower Cranes (10–16 tons) | 2.0 m – 3.0 m | Medium to Heavy Loads |

| Large Tower Cranes (20+ tons) | 3.0 m – 4.5 m+ | Heavy Duty Applications |

Note: Sizes vary depending on the manufacturer and specific project requirements. Some projects even require custom-designed slewing rings for special applications.

Types of Slewing Bearings for Tower Cranes

Not all slewing bearings are the same. Their internal design and rolling elements can vary, which directly affects their performance and load capacity. The most common types used in tower cranes are:

Single-Row Ball Slewing Bearing

It uses a row of steel balls as the rolling elements, with the steel balls in four-point contact with the raceway. It can simultaneously withstand axial force, radial force and overturning moment. It is the preferred product for small and medium-sized slewing bearings with a diameter of less than 2000mm.

- Simple structure, lightweight.

- Suitable for smaller tower cranes with lower load requirements.

Double-Row Ball Slewing Bearing

The contact Angle of the upper ball reaches 90 degrees, it has a three-piece structure, and its cross-sectional dimension is much larger than that of a single ball. Under the condition of maintaining the same load-bearing capacity, it can be fully used interchangeably with single-row ball slewing bearings and double-row eight-point contact ball slewing bearings.

- Can handle larger axial loads and tilting moments.

- Often used in medium-sized tower cranes.

Three-Row Roller Slewing Bearing

Suitable for larger loads, they are the most cost-effective among slewing bearings with diameters greater than 2000mm.

- Provides the highest load capacity.

- Widely applied in large tower cranes for heavy construction projects.

| Type | Structure | Load Capacity | Typical Application |

| Single-Row Ball | One raceway with steel balls | Light | Small tower cranes |

| Double-Row Ball | Two raceways with balls | Medium | Medium tower cranes |

| Three-Row Roller | Three independent raceways with rollers | Heavy | Large tower cranes |

By selecting the correct type, you ensure that the tower crane operates safely and efficiently under expected working conditions.

How to Choose the Right Slewing Bearing for Your Tower Crane?

Choosing the right slewing bearing is crucial for both safety and efficiency. The following are the main factors to be considered:

- Crane model and load capacity: Ensure that the bearings are compatible with the specific tower crane design and its rated load.

- Load requirements: Consider the expected axial load, radial load and overturning moment of the project.

- The working environment: Outdoor cranes will be affected by wind loads, dust, temperature fluctuations and moisture. Bearings should be designed with good sealing performance and corrosion resistance.

- Maintenance requirements: Bearings with a more complete lubrication system and better wear resistance can reduce downtime.

- Supplier reliability: Always source from trusted manufacturers to ensure quality, accuracy and after-sales support.

Ready to Upgrade Your Tower Crane Performance?

The slewing bearing of a tower crane is not merely a component but also the pillar of the crane’s rotating system, ensuring safety, accuracy and efficiency. In addition to tower cranes, slewing bearings are also widely used in cranes, mining machinery, construction equipment and other heavy-duty applications.

CPTC not only offers standard slewing bearings, but also designs, develops and manufactures customized solutions with special structures based on the specific needs of customers. Whether you need a reliable alternative to a tower crane or need to customize slewing bearings for a specific project, CPTC can serve you with its expertise.

Contact us immediately to learn how CPTC slewing bearings can enhance the performance and service life of your tower cranes and heavy machinery.

Related Products

Tower Crane Trolley

Multiple functions

Intuitive operation

Tower Crane Trolley Mechanism

Tower Crane Trolley Chassis

Withstands heavy loads and forces

Works with supporting…

Tower Crane Trolley Device

Multiple functions

Intuitive operation

Tower Crane Trolleying Limit Gear

Controls luffing motion

Improves safety and efficiency

Enables dynamic boom…