Bridge inspection, maintenance, and construction demand highly specialized access equipment. One of the most efficient and safe tools used today is the under bridge suspended platform. Whether you’re repainting a highway bridge, inspecting joints and beams, or performing structural maintenance, a suspended bridge platform can make all the difference in safety and efficiency.

In this article, we’ll walk you through what these platforms are, how they work, and—most importantly—how to choose the right model for your specific bridge project.

What Is a Suspended Platform for Bridge Work?

A mechanical access system known as a suspended platform for bridge work enables workers to operate directly underneath or alongside a bridge. These platforms are most often suspended from the bridge deck or attached using overhead suspension arms, allowing for vertical or lateral movement, and are supported by high-strength steel cables.

To provide a safe and stable working surface in hard-to-reach regions, suspended platforms work well for:

- Bridges inspections, assessments, and evaluations

- Painting and application of anti-corrosion coatings

- Cable and overhead line maintenance, tensioning, or servicing

- Repairs and reinforcement involving concrete

- Installation of utility lines or sensors for utilities

Unlike traditional scaffolding, suspended bridge platforms provide the advantage of rapid deployment and facilitated movement, which in turn saves time and reduces labor expenses.

The Common Specifications and Models of Suspended Bridge Platforms

In the field of bridge construction and maintenance, the suspended platforms for bridges, as the core operating platform, their specification and model compatibility, and construction efficiency directly affect the project quality.

Common types include:

- Single-point suspended platforms: A small and compact platform, used for quick inspection or minor maintenance.

- Two-point suspended platforms: The most common design, used on the surface of medium-sized Bridges.

- Multi-point modular suspended platforms: Specifically designed for large bridge projects with extensive working areas.

- Telescopic or cantilever under-bridge platforms: Suitable for deep cantilever structures or situations where the bridge deck cannot directly support and suspend.

Typical specifications include:

- 8-meter standard section: It is suitable for local maintenance of urban elevated Bridges and river-crossing beam Bridges. It can bear a load of up to 500kg on one side and meet the requirements of 2-3 people working simultaneously.

- Specifications of 12 meters / 16 meters: Corresponding to conventional expressway Bridges (width 12.5-16 meters), it can cover typical working conditions such as replacement of bottom supports of beams and crack repair. The platform width is 1.2 meters, equipped with anti-slip grilles and guardrails to ensure operational safety.

- The 20-meter super-long section: For special structures such as cross-sea Bridges and canyon suspension Bridges, high-strength Q345 steel is used, with the load-bearing capacity increased to 800kg. It is combined with a wireless remote control system to achieve the operation of crossing piers and obstacles.

How Does a Suspended Bridge Platform Differ from Traditional Scaffolding?

While both systems aim to provide elevated access, suspended platforms and traditional scaffolding differ significantly in function and efficiency:

| Feature | Suspended Bridge Platform | Traditional Scaffolding |

| Installation Time | Fast – Can be deployed in hours | Slow – May take days to install |

| Mobility | High – Easily repositioned | Low – Fixed once installed |

| Cost Efficiency | High for short/medium-term use | High for long-term static use |

| Access Versatility | Excellent for under and side areas | Limited to side or vertical walls |

| Safety | Equipped with modern safety systems | Depends on manual setup |

In most bridge maintenance projects, under bridge suspended platforms offer better flexibility and safer working conditions, especially in high-altitude or confined scenarios.

What Is the Load Capacity of Under Bridge Suspended Platforms?

Ensuring the suspended platform’s load-bearing capacity is one of the most key indicators of performance. This capacity determines the number of workers as well as the type of tools or materials that can be safely moved during an operational procedure. Thus, it has become the concern of both engineering technicians and construction managers.

The carrying capacity depends on the following factors:

- Material selection: the platform suspended’s load-bearing capacity is directly proportional to the using frame’s high-strength steel. The frame’s increased weight will enable it to bear greater load.

- Structural design: the load-bearing performance of the hoist basket is increased by effective platform design that includes a reasonable structural layout, fortified connection points, and optimized platform area. This design should also account for environmental factors, for instance, resilience to earthquakes and wind.

- The lifting Equipment Power: the platform motor and gear strength alongside power will determine the lifting capacity.

- Safety accessories and equipment: the lifting basket’s load-bearing capacity can be safened by installing auxiliary devices, for instance, safety ropes, anti-overturning devices, and buffers.

- Span and platform length: Wider platforms may necessitate additional reinforcements to better sustain the load.

A typical platform’s load-bearing capacity ranges from 250 to 1,000 kilograms. Nevertheless, custom platforms can be engineered to accommodate greater load requirements.

Important Note: It is critical to verify the platform’s manufacturer listed load limit and confirm that the platform has passed relevant safety certifications, which include CE, ISO or ANSI standards.

How to Choose the Right Suspended Platform? – Focus on These 3 Key Parameters

Choosing the ideal suspended platform for bridge operations can double the efficiency of high-altitude work. This is not merely about price and availability. You must assess whether the system is suitable for your specific project requirements.

Is the Load Capacity Suitable for Your Job Requirements?

First, let’s look at the carrying capacity. The total load is calculated based on the number of workers and the weight of materials. The rated load capacity of commonly used hoists in bridge construction is divided into three grades: 200kg, 500kg, and 800kg. For construction on the outside of high-speed railway Bridges, if three people are needed to work with tools, it is more reliable to choose the 500kg grade, leaving a 20% safety margin.

Does the Working Range Match the Bridge Structure?

Not all Bridges are designed the same. Please check:

- Bridge height and clearance – Can the platform easily reach below?

- Span and overhang – Is the horizontal extension of the platform sufficient?

- Will the installation or suspension of the access point – platform not cause interference to the structure?

In complex structures, it is recommended to use modular or telescopic platforms as they can be adjusted to adapt to irregular geometries.

Are the Safety Features Fully Equipped?

Give priority to models with dual anti-fall devices and emergency manual descent devices. For rail-mounted hoists, it is also necessary to check the sensitivity of the rail clamps to ensure stable locking even in a 4-level wind environment.

Make sure the platform includes the following configurations:

- Emergency stop and descent system

- Overload protection

- Anti-fall device and safety belt fixing points

- Anti-sway and anti-tilt devices

- Automatic limit switches for height control

- Surge protection for electrical systems

Reputable manufacturers will provide test certificates and security logs along with their platforms. Please be sure to ask for these documents before purchasing or renting.

Professional Suspended Platforms Make Bridge Work Safer and Faster

Suspended platforms are a contemporary solution of great efficiency for works related to bridges. They allow for safe and stable access to construction areas which are difficult to reach, both beneath and alongside the bridge.

In the event that a business is considering purchasing or renting a professional grade under bridge suspension platform, it is important to emphasize the contractor’s qualifications, especially concerning safety and technical project documentation, platform customization, and client-specific requirements.

CPTC is a leading enterprise in the field of suspended passage solutions, providing customized under-bridge platforms designed to ensure safety, durability and optimal performance in the demanding environment of bridge construction and maintenance.

Related Products

ZLP Series Suspended Platform

Simple and quick installation

Multiple security measures

Stable and…

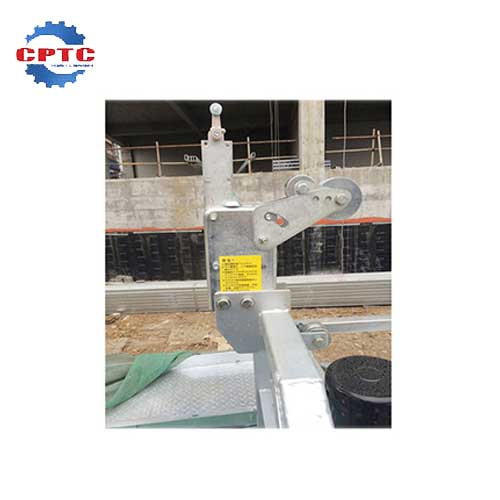

Suspended Platform Safety Lock

Easy to Operate and Use

Made…

Construction Platform

With a lightweight…

Limit Switch

Compact and Lightweight

Easy Installation