Tower cranes rely on the hoisting mechanism as the heart of their lifting capacity and protective circuitry. Within this assembly, the braking system functions as the sentinel, delivering the millisecond control needed to keep loads steady and to avert free-fall incidents. Selecting the appropriate brake remains a non-negotiable part of the rig design process, since the choice informs efficiency, upkeep, and the fundamental level of operational safety.

The current marketplace provides two predominant designs: electromagnetic and hydraulic brakes. Each design offers distinct benefits, operational constraints, and suitability ranges. In the following sections, we will systematically examine the braking characteristics of these two systems, present a detailed comparative matrix, and briefly survey a few specialized options. The objective is to furnish operators and engineers with comprehensive technical guidance, thereby supporting the adoption of the solution that best fulfills the lift mission while balancing performance and risk.

Electromagnetic Brakes in Tower Crane Hoisting Mechanisms

The electromagnetic (EM) brake is the most common type of brake in the hoisting mechanism of modern tower cranes, especially suitable for medium and small-sized cranes. They are renowned for their reliability, rapid response and fail-safe design. The braking principle is to use an electromagnet to attract the brake pads of the brake, thereby achieving the braking effect. The two most common types of brakes in tower cranes are:

- Electromagnetic Drum Brakes – These consist of a drum attached to the hoisting motor shaft, with a brake lining pressed against it via magnetic force.

- Electromagnetic Shoe/Block Brakes – Here, brake shoes or blocks press directly onto a rotating wheel or drum to create friction.

Electromagnetic Brakes: Advantages vs Limitations

| Advantages | Limitations |

| Simple design – Fewer mechanical components mean easier installation and less likelihood of mechanical failure. | High braking impact – Braking can be abrupt, causing load shock if not carefully controlled. |

| Cost-effective – Lower manufacturing and maintenance costs compared to hydraulic systems. | Limited heat dissipation – Continuous heavy lifting can cause overheating. |

| Ease of maintenance – Components are generally accessible and simple to service, reducing downtime. | Not ideal for heavy loads – Better suited for small to medium tower cranes or cranes with infrequent lifting cycles. |

Typical Applications

Electromagnetic brakes are usually installed on mid and small tower cranes, especially on job sites with medium load capacities. Its simplicity, ease of use, and low price ensure that it is most desirable for cranes operating under urban or low-rise conditions.

Apart from that, electromagnetic brakes are also used extensively in apparatus employed in transmission such as hoists and belt conveyors.

Hydraulic Brakes in Tower Crane Hoisting Mechanisms

Hydraulic brakes are another commonly used type of brake, typically applied in scenarios with low working frequencies and heavy loads, such as large tower cranes and bridge cranes. Its working principle is to transmit the braking torque from the hydraulic cylinder to the brake through the hydraulic transmission mechanism, thereby achieving the braking effect. The two common types are:

- Hydraulic Thruster Brakes – Activated by hydraulic cylinders or push rods that press the brake pads against the drum.

- Electro-Hydraulic Block Brakes – Combine electrical controls with hydraulic actuation for precise braking control.

Hydraulic Brakes: Advantages vs Limitations

| Advantages | Limitations |

| Smooth operation – Gradual engagement and release minimize load shock. | Higher cost – More components and systems raise initial investment. |

| High reliability – Suitable for heavy loads and frequent lifting cycles. | Complex system – Requires hydraulic lines, pumps, and regular checks. |

| Long service life – Less mechanical stress and wear compared to electromagnetic brakes. | Maintenance demands – Issues like leaks, fluid degradation, or contamination can affect performance. |

Typical Applications

Hydraulic brakes are preferred for large or heavy-duty tower cranes, especially those operating in industrial or high-rise construction environments. They provide the control and durability required for frequent and high-load lifting operations

Electromagnetic vs Hydraulic Brakes: A Comprehensive Comparison

In practical applications, tower cranes often use both electromagnetic brakes and hydraulic brakes to fully utilize their respective characteristics and improve the braking performance of the entire mechanism. Below, we will discuss the differences between the two types of brakes in detail. By combining text and tables, crane operators can quickly see which brake type aligns with their operational needs.

Braking Performance

- Electromagnetic: Rapid engagement, can cause abrupt stopping under load.

- Hydraulic: Smooth and gradual, ideal for heavy or delicate loads.

Installation & Cost

| Feature | Electromagnetic Brake | Hydraulic Brake |

| Initial Cost | Low | High |

| Installation Complexity | Simple | Moderate to Complex |

| Space Requirements | Compact | Larger footprint due to hydraulic components |

Maintenance & Lifespan

- Electromagnetic: Easier maintenance, shorter lifespan under heavy use.

- Hydraulic: Requires fluid checks, but longer lifespan under heavy-duty operations.

Suitable Crane Applications

| Brake Type | Optimal Crane Size | Usage Frequency | Load Conditions |

| Electromagnetic | Small to Medium | Moderate | Light to medium loads |

| Hydraulic | Large | Frequent | Heavy loads / High-rise construction |

Other Less Common Tower Crane Brake Types

While EM and hydraulic brakes are the dominant technologies, a few others are used, often as secondary or auxiliary systems:

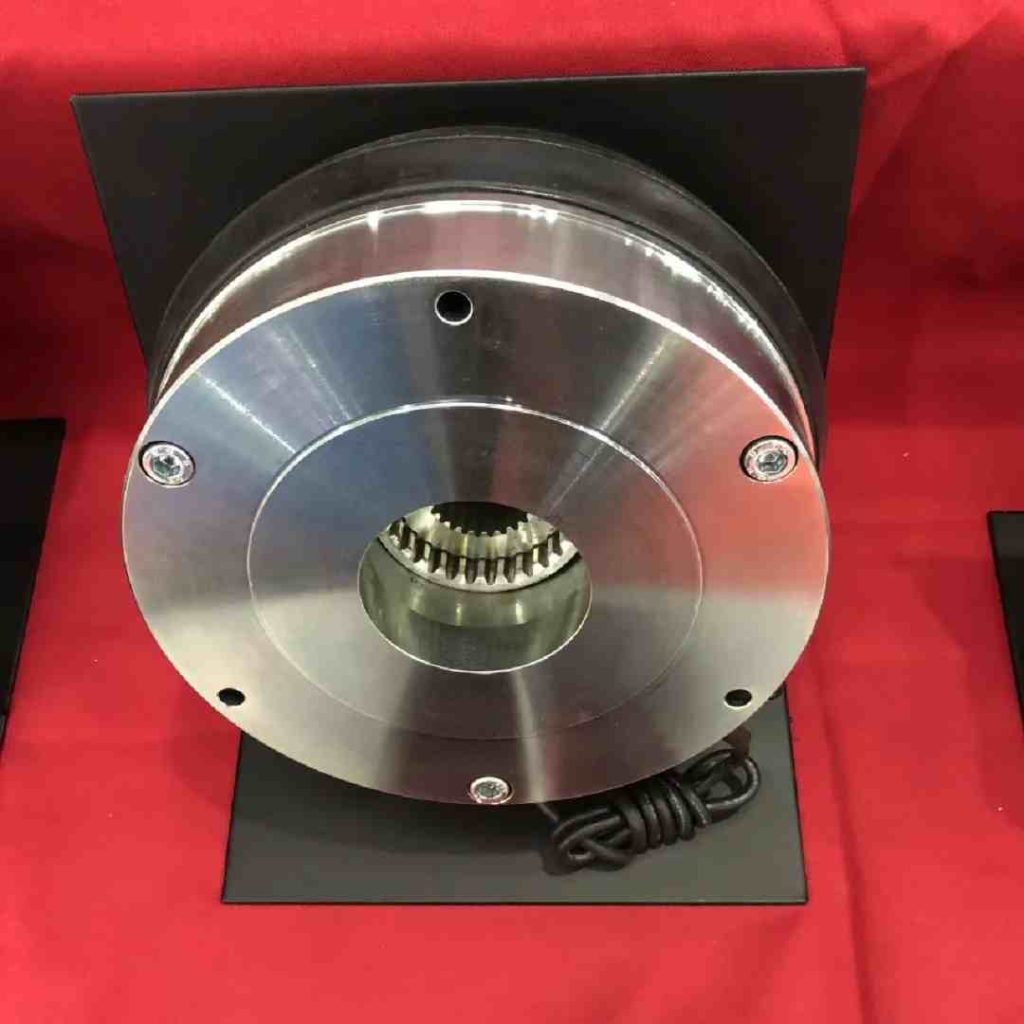

Disc Brakes

- Operate like automotive brakes, with friction pads pressing a rotating disc.

- Excellent heat dissipation and smooth braking.

- Used in high-end tower cranes as a modern alternative.

Pneumatic Brakes

- Utilize compressed air to actuate the brake.

- Rare in tower cranes, mostly used in special machinery or industrial settings.

Fail-Safe Brakes

- Automatically engage in the event of power loss or system failure.

- Often integrated with electromagnetic or hydraulic systems for enhanced safety.

These types are supplementary options and generally appear in specialized applications rather than standard construction cranes.

Selecting the Right Brake for Your Tower Crane

Selecting the optimal hoisting brake for tower cranes involves balancing several parameters: crane size, typical lift frequency, maximum load, and job-site environment.

- Electromagnetic types combine low initial cost with straightforward upkeep, hence they fit small to medium cranes dealing with balanced daily workloads.

- Where demand peaks, large cranes lift heavy or compacted loads several times per hour. Hydraulic units excel here, delivering deceleration that is steady yet proportional to load variations.

- Niche cranes, for instance those lifted frequently near sensitive loads, may specify disc, pneumatic, or spring-applied hydraulic brakes that augment or substitute the primary system with added fail-safe features.

Assessment must include these conditions:

Braking Torque: The system must generate sufficient torque to halt the hoist and swing motions within the figures mandated by the load chart and by the stopping distance tolerance.

Durability: Materials and design must resist corrosion, grinding, and thermal fatigue, thereby safeguarding reliability over extended shifts or seasons.

Safety Integrity: The brake must operate within tolerances until the prescribed service gap, must demonstrate rapid, predictable deceleration to bay loaded hoisting members, and must include hardware that guards against total loss.

Through adherence to such parameters during the design-review or procurement process, project teams align braking resources with tower crane mission profiles, thus safeguarding personnel, compressing maintenance frequency, and maximising asset longevity.

Related Products

Tower Crane Pinion – 99/38/19 teeth

Steel Wire Rope | CPTC-CHINA

Casting Tower Crane Pulley

High strength;…

Tower Crane Hoisting Device

Smooth operation, precise control

Highly adaptable