Tower cranes are the pillar of today’s construction technology, allowing contractors to install and set heavy loads with precision at a high height. At the heart of every tower crane’s vertical structure lies a critical component—the mast section. As a project manager, crane operator, or procurement specialist, an understanding of tower crane system mast sections is key to ensuring safety, compatibility, and optimal functionality. This article elaborates at length regarding tower crane mast sections, such as their type, specifications, selection criteria, etc.

What Is a Tower Crane Mast Section?

The mast section of a tower crane is a modular steel structure primarily used to support the crane’s vertical height and maintain overall stability. Typically made of high-strength steel, mast sections are the components that connect to form the central tower or “mast” of the crane.

These mast sections are stacked on top of each other and secured with pins or bolts, allowing the crane to reach different heights based on project requirements. At the same time, they play a critical role in enabling the crane to withstand vertical loads (from the crane itself and the materials being lifted) and horizontal forces (such as wind pressure).

The Importance of Tower Crane Mast Section

A good mast section for tower crane is necessary for the following reasons:

- Structural Stability: It sustains the vertical position of the crane during use.·

- Height Adjustment: Modular construction allows the crane to be elevated or lowered to different heights based on phases of a project.·

- Load Bearing: The mast section is responsible for bearing the full load from the jib, counterweights, and the material being hoisted.

- Safety: Properly engineered and maintained mast sections prevent dangerous structural failures or collapses.·

Without a reliable tower crane mast section, even the most advanced crane models would be unusable on multi-story construction projects.

Types of Tower Crane Mast Sections

Tower crane mast sections vary by connection method, shape, load capacity, and application. Here’s a breakdown:

Classified by Connection Method:

● Bolted Mast Sections

These are the most common types. Mast sections are connected using high-strength bolts and nuts at their junction flanges. They offer strong structural integrity, easy maintenance and disassembly, and compatibility with most tower crane brands.

● Pinned Mast Sections

Pinned sections use heavy-duty steel pins instead of bolts to join the sections together, offering faster installation and removal, slightly more flexibility under certain conditions, and are commonly found in specific crane models or older designs.

Classified by Cross-Section Shape:

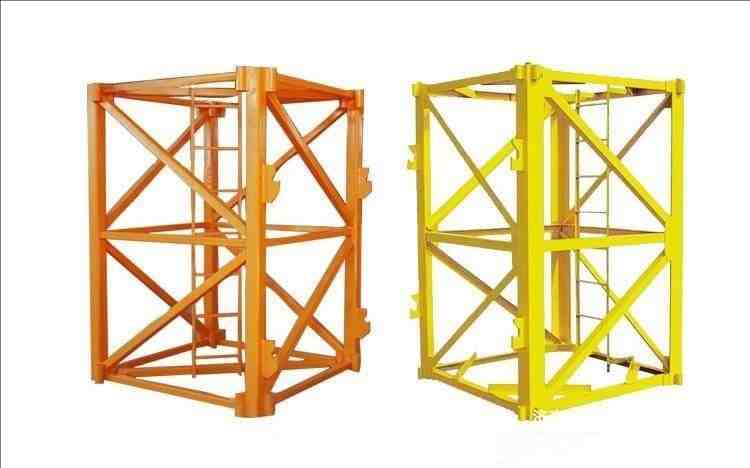

● Square Mast Sections

Square Mast Sections are the most commonly used tower shape in modern tower cranes due to their balanced design and structural advantages. The symmetrical geometry evenly distributes stress on all sides of the tower, helping to minimize weak points and increase the overall load-bearing capacity of the crane. This design ensures the stability of the equipment even under heavy loads and strong wind conditions. In addition, the standardized size of Square Mast Sections is also easier to transport and store, meeting the replacement needs of the construction site.

● Rectangular Mast Sections

Rectangular mast sections are less commonly used compared to their square counterparts but still play an important role in specific tower crane applications. Their elongated shape can be particularly advantageous in projects with space constraints, such as construction sites in narrow urban areas or locations with limited clearance. The design of rectangular mast sections allows for a more compact footprint while still providing adequate structural support. Additionally, they are often utilized in cranes with specialized load configurations or unique operational requirements, where tailored mast geometry can help optimize balance, lifting performance, or structural integration with surrounding elements like scaffolding or building frameworks.

● Classified by Size and Load Capacity

Choosing the correct size is essential for load-bearing calculations and ensuring the structure doesn’t buckle under operational stress. Mast sections also differ in:

Dimensions: Common sizes include 1.6m × 1.6m, 2.0m × 2.0m, or custom configurations

Wall thickness: Heavier sections support larger loads

Material grade: Often made of Q345B or Q235 steel

Special-Purpose Mast Sections:

● Transition Sections

Used to connect two different sizes or types of mast sections. These are crucial when upgrading or modifying an existing tower crane.

● Base Sections

These form the foundation of the mast tower and are anchored to concrete or ballast blocks. They distribute the crane’s weight and stabilize the entire structure.

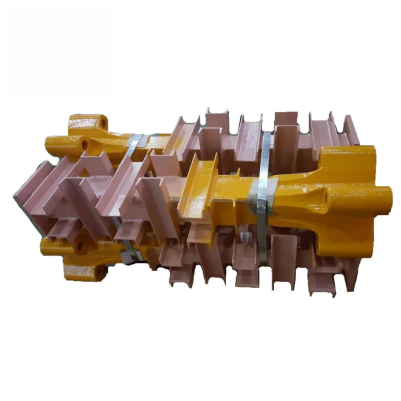

● Climbing Sections

Used in internal climbing cranes, these sections help the tower crane “climb” a building as it grows taller during construction. Climbing sections are highly engineered and require expert installation.

How to Choose the Right Mast Section of Tower Crane

Selecting the right mast section for tower crane applications involves several key considerations:

Select the Right Mast Section Based on the Tower Crane Model

Not all mast sections are universal. Ensure that the mast section is compatible with the tower crane’s brand and model (e.g., Potain, Liebherr, Yongmao, etc.).

Determine mast section type and quantity based on height and load requirements.

By calculating the maximum required crane height and lifting capacity, you can determine both the number of mast sections needed and whether to use reinforced or standard sections.

Check Brand Compatibility and Interchangeability

Some crane systems follow standard interchange formats such as F0/23B, L68B1, or MC85. If using mast sections from different sources or suppliers, always verify:

- Connection plate compatibility

- Pin/bolt alignment

- Structural load certifications

Certification and Quality Standards

Ensure the mast section complies with international or local safety and quality standards such as CE (Conformité Européenne), ISO 9001 Quality Management, and SGS testing certification. Adhering to these standards guarantees that the tower crane mast section meets essential requirements for structural integrity, safety, and long-term durability.

Conclusion

Identification of the mast section of tower crane systems is necessary for every construction specialist dealing with high-rise buildings or heavy-duty lift processes. Ranging from structural types and connection methods to selection standards and certifications, this component contributes a significant role in project security, crane efficiency, and operation success.

No matter if you’re purchasing new equipment, replacing the compromised components, or just augmenting your pool of knowledge, understanding how to evaluate and choose the correct mast section for tower crane work will help you make better, safer decisions.

FAQs about Tower Crane Mast Sections

Q1: Can I use mast sections from different crane brands interchangeably?

A: Not always. While some models follow common standards like F0/23B or L68B1, compatibility should be verified based on structural design and connection interfaces.

Q2: How often should mast sections be inspected?

A: Visual inspections should be done before every installation. Full structural integrity inspections (including weld checks and rust assessment) should occur every 6–12 months.

Q3: Are galvanized mast sections better than painted ones?

A: Galvanized mast sections offer superior rust resistance and are ideal for long-term or coastal projects. Painted sections require more frequent maintenance.

Related Products

Tower Crane Mast Section

Steel pipe construction

Comprehensive spare parts

Safety, stability, reliability

Tower Crane Wall Tie

Vertical support

Safety enhancement

All Kinds of Tower Crane Fixing Angle

Good stability

Lightweight