The gearbox in a construction hoist is tasked with converting motor power into mechanical torque necessary to lift and lower heavy loads. One of the drive system’s components that is crucial to the operation, its performance has a direct impact on the reliability, safety, and efficiency of the entire machine. However, due to the fact that construction sites are laden with harsh environments and heavy usage, the drive train is liable to be damaged and worn out if not kept in check.

Extending the lifespan of a construction hoist gearbox is not just about cutting costs on replacement parts — it’s about continuous operation, staying away from downtime, and guaranteeing safety on the ground. On this article, we will share the most vital considerations that affect the lifespan of the gearbox and provide helpful tips to help you get the best out of your construction hoist gearbox.

Why Gearbox Lifespan Matters in Construction Hoists

The gearbox is the construction hoist’s operational ‘center’ and if it fails, it renders the entire lifting mechanism useless—this may create delays as well as unsafe conditions. Examples of this might include:

- Greater chance of an accident or breakdown occurring with the hoist.

- More expensive repairs and replacement of parts needed for maintenance.

- Stagnant progress and halted movement vertically due to project standstill.

- Inefficient use of labor resources, equipment lowered productivity.

Smoother operation while lifting, less frequent servicing, and reduced ownership costs in the life cycle of the construction hoist are all achievable outcomes by keeping gearboxes in good condition and regularly serviced.

Top Factors That Affect Gearbox Longevity

Gears can develop issues for a variety of reasons, however not all problems stem from the same underlying cause. Identifying what may weaken or reduce the efficiency of a gearbox system is crucial to maintaining its functionality and preventing breakdowns in the long run. Factors include:

Improper Lubrication

A gearbox’s rated lifting hoist comes with incrementally dangerous excess weights that if misplaced or unevenly loaded—common in construction environments—apply shock loads internally stress fatigue and failure. This places an enormous strain on the gearbox as well as accelerate failure.

Overload or Shock Loads

Exceeding the hoist’s rated lifting capacity places enormous strain on the gearbox. Sudden or uneven loads — common in construction environments — can result in shock loads that stress internal components, accelerating fatigue and failure.

Poor Alignment with the Motor

Misalignment between the motor and gearbox can cause vibration, uneven gear meshing, and additional mechanical stress. Even slight misalignment can reduce the efficiency of power transmission and cause premature bearing and shaft wear.

Dust, Moisture, or a Poor Working Environment

Construction sites are often riddled with dirt which contains moisture that can compromise seals due to providing pores for dust particles and other unknown liquids from entering. For prolonged periods without support these conditions can wreak havoc by causing corrosion which drastically reduces the operational lifespan of gearboxes while simultaneously damaging lubricants.

Low-Quality Gearbox Components

Cutting corners on design or manufacture will often result in lower-quality parts for a gearbox. In turn, this results in less effective materials being utilized, which places limits on accuracy and the lifespan of the part. In any case, spending money on improperly manufactured components is a false saving.

Practical Tips to Extend Service Life

It may not be as complex, but prolonging the servicing life of your hoist gearbox requires an extraordinary commitment to detail and compliance with principles.

Use the Right Lubricant and Replace It Regularly

Damage to any machinery components can arise from failing to use appropriate lubricants that comply with the gear box manufacturer’s prescription. The viscosity and type of oil together with its additives ought to align with the operational conditions of the gearbox. Depending on how often these components are used, complete system inspections including oil checks should be performed alongside ensuring environment considerations too. Inspect for signs of contamination and product deterioration, noting discoloration or the presence of stray metallic particles.

Avoid Overloading and Frequent Start-Stops

Under no circumstances should the load bearing capacity be exceeded on the hoist system as it can worsen operational safety, strain the gearbox and inflict undue risk on processes during operations should failures occur at uncontrolled conditions. Also avoid systems that exhaust excessive internal gears/ bearings due to frequent start-stop cycles. Equipment modifications such as soft start control systems can aid in damping mechanical forces during restarts or shutdowns helping overall equipment reliability.

Ensure Proper Installation and Alignment

During installation or maintenance, always check the alignment between the motor shaft and gearbox input shaft. Use precision alignment tools if necessary. Misalignment often leads to vibration, increased energy consumption, and accelerated wear. Also, make sure the mounting structure is stable and free from excess vibration.

Maintain a Clean Operating Environment

A construction site might not be effortlessly kept tidy, but it is essential to focus on the protection of the gearbox. To minimize the entrance of dust, debris and moisture use protective weatherproof gear and sealed enclosures. Make sure that the seals of the gearbox are functioning properly. Replace them immediately if any leakage has been detected.

Choose High-Quality Gearbox from Trusted Suppliers

For proper construction hoists take specific care to invest in a properly designed gearbox. Known brands usually subject their products to rigorous testing and utilize materials specially crafted for high-stress environments with extensive wear cycles. Search for products containing double lip seals, temperature-resilient lubricants, hardened gears and so forth.

Recommended: For efficient hoist system gearboxes, CPTC provide construction lift motors and gearboxes specifically built to provide optimum durability alongside efficiency while upholding safety measures. Their heavy-duty gearboxes are equipped with precision-engineered components coupled with a high-torque output which proves beneficial during strenuous lifting operations.

When to Replace or Repair Your Hoist Gearbox

The service life of a hoist gearbox that has been well maintained will eventually come to the natural end due to external factors. Here are some indicators that it may be time for a servicing action or replacement:

- Operating noises which were previously absent begins exhibiting sounds like grinding, whining, and knocking.

- A noted increase in heat/vibration during normal operations benchmarked against historical data.

- Oil leakages contaminated beyond acceptable includes the lubricating medium(for gearboxes).

- Physically observable fractures, corrosion, or misalignment components upon inspection Also termed as structural damage outside ‘normal’ appearance standards.

From a repair versus replace standpoint deciding factor considerations should comprise of lower bound age metrics to hours spent (+part cost) vs breakdown incidences +average used norm for replacement(averaged metric 5–7years old generally accepted ‘red flag’ threshold)-replacement fiercely ought prove more optimal(pocket friendly post breakdown metric).

It’s also wise to schedule routine inspections every 3–6 months, or after every 500 hours of operation, especially in high-load or high-dust environments. Early detection of wear or imbalance can prevent catastrophic failure.

Need Reliable Motor and Gearbox Solutions for Construction Hoist?

The gearbox is an essential component of a construction hoist’s lifting system, and its performance directly influences the reliability and safety of vertical transport on-site. By understanding what factors affect gearbox life and implementing best practices — such as proper lubrication, avoiding overloading, ensuring alignment, and choosing quality products — you can significantly extend its service life.

Regular maintenance and timely interventions will not only reduce unexpected downtime but also maximize the return on your equipment investment.

Explore CPTC’s heavy-duty gearbox lineup — engineered for high torque, low maintenance, and maximum uptime in demanding construction environments.

Related Products

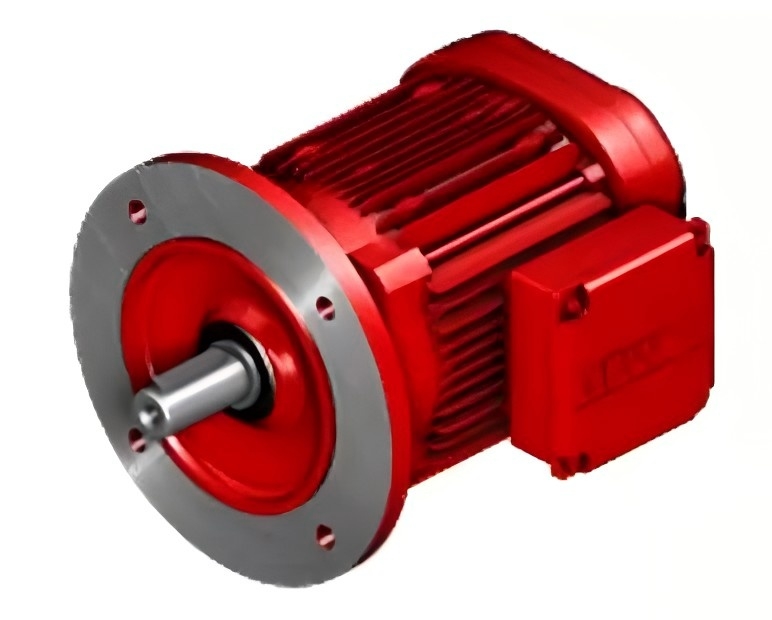

Motor and Gearbox for Construction Hoist

Rugged structure;

Three-phase motor;

GJJ, BAODA;

For construction hoists/ material and…

Nord Motor & Nord Gearbox

Quality assurance

Rich products

CPTC supply

Sew Motor & Sew Gearbox

SEW drive experts

Customized and efficient

Innovative and energy-saving

Construction Hoist Drive Device

The YZZl32M-4 motor

The core of the elevator drive and…