Tower cranes are vital for modern construction projects as they can lift and transport construction materials and other heavy goods vertically. However, these cranes are susceptible to many forces such as wind, dynamic loads, and the heavy loads they are meant to lift. Improperly supporting and anchoring these machines can result in severe consequences such as the collapse of construction equipment, significant property damage, or in the worst scenario, the loss of human life.

The fixing angle of a tower crane is one of the most important parts which is responsible for the stability of the crane and which is also ignored by a good number of people. The fixing angle is much more pivotal as it ensures the stability of the crane by linking its base part of the superstructure to the foundation. This article will focus on defining the fixing angle for tower cranes, the mechanism of its operation, and its importance to the safe operation of the tower cranes on site.

What Is a Fixing Angle for Tower Cranes?

A fixing angle for a tower crane is a structural element like a right-angled steel bracket or plate which serves to fix the crane’s base to the concrete foundation. Often, it is placed alongside anchor bolts, and is either welded or embedded in the base frame of the tower crane section. The fixing angle serves to strengthen the mechanical attachment of the steel mast to the reinforced concrete footing.

The angle fixing some parts of a crane and its manufacturer could be of various shapes and sizes. Most are made from high strength steel like Q235, or Q345, having shapes like L and T, or even custom. Regardless of shape, all of them serve the same purpose which is to maintain vertical alignment between the crane’s base and the supporting surface while countering lateral forces and distributing stress.

To summarize, a fixing angle is a crucial component in the tower and base intersection of a crane that enables them to be a single and stable entity during operation.

How Fixing Angles Contribute to Tower Crane Safety and Stability

The role of a fixing angle goes far beyond just holding the crane in place. It’s an active component in a complex system of force management. Here’s how they ensure the crane remains safe and stable.

Anchoring and Preventing Overturning

The most obvious function is to anchor the crane. By bolting the mast to a foundation that can weigh hundreds of tons, the fixing angles create an incredibly stable base. The primary force they resist is the bending moment, which is the rotational or turning force that tries to tip the crane over. This moment (M) is a product of the force (F) and the distance (d) from the pivot point:

M=F×d

In a tower crane, massive moments are generated by:

- The weight of the long horizontal jib.

- The weight of the counterweights on the shorter arm.

- The weight of the load being lifted at a distance from the tower.

- The force of the wind pushing against the entire structure.

The fixed Angle steel and its anchor bolts work together to counteract this rotational force. The bolts on one side of the crane that are “lifted” by the moment are subjected to tensile force (tension), while the bolts on the other side are subjected to compressive force (thrust). The design of the Angle steel aims to transfer these tensile and compressive forces to the concrete foundation without failure, thereby effectively preventing the crane from overturning.

Distribute vertical and horizontal loads

Tower cranes bear various forces, and the Angle steel must be capable of safely controlling these forces:

- Static load (vertical force) : This is the static weight of the crane structure itself, including the mast, boom, balance boom and mechanical equipment. The Angle steel evenly distributes this huge weight in the anchor bolt area and the foundation.

- Live load (vertical force) : This is the dynamic weight of the lifted material. When the trolley moves the load along the boom, the force on the Angle steel will change. Therefore, the Angle steel must be strong enough to withstand these constantly changing stresses.

- Wind load (horizontal force) : The wind exerts a significant horizontal force on the large surface area of the crane. This force will generate bending moments and shear forces – these forces will attempt to cause the crane base to slide sideways from the foundation. Firmly bolted Angle steel can prevent such lateral movement.

- Torsional load: Wind blowing at a certain Angle or the rotation (rotation) movement of a crane will generate torsional force on the mast, that is, torque. The rigid square structure of Angle steel can effectively resist this kind of torsion.

By effectively transmitting all vertical, horizontal and rotational forces to the ground, Angle steel ensures that the crane operates from the zero point of motion, which is precisely the definition of stability.

Installation Best Practices for Fixing Angles

Fixing angle installation for a tower crane requires precision, high-quality materials, and scrupulous execution of safety measures. Incorrect installation can jeopardize the overall structural integrity of the crane.

Pre-Alignment and Measurement

The foundation bolts and crane base need to be accurately aligned prior to installation. The fixing angles need to be measured and installed according to the fixing angles manufacturer’s specifications and local building codes.

Bolting vs. Welding

Angles may be bolted or welded on the crane base:

- Bolting is easier to disassemble and adjust.

- Welding offers a stiff and permanent attachment but requires performance by certified welders with inspection.

- Both methods are utilized together in case of high-rise or tower cranes of prolonged utilization.

High-Quality Materials

Angels for fixing must be made of corrosion-resistant and load-rated material. Installation outdoors is done by using anti-rust coating and hot-dip galvanizing.

Periodic Inspection

Routine inspections following installation must be arranged. Look out for signs of:

- Cracking or deformation around the fixing angles

- Bolt loosening or weld failure

- Corrosion or rust reduction of strength

Conformity to Standards

Conform to safety standards like ISO 12485, EN 14439, or national crane installation regulations where necessary. Always refer to the manufacturer’s installation guide for a crane.

When and Where Fixing Angles Are Most Critical

Fixing angles play an essential role throughout the tower crane’s service life, but there are specific stages and conditions where their role becomes especially critical:

1. Initial Crane Installation

During the first erection of the tower crane, the fixing angle ensures the crane is anchored safely before any climbing or height extension begins. It’s the first structural element connecting crane and ground.

2. High Wind Environments

On sites with high wind exposure, fixing angles provide extra lateral stability and resistance to overturning moments, especially when the crane is idle or free-standing.

3. Crane Climbing and Extension

When the crane climbs using a top or internal climbing system, the fixing angle must withstand additional forces during temporary imbalance or vertical jacking.

4. Near Tall Structures or in Confined Areas

When cranes are erected near buildings or in limited-access areas, fixing angles support base precision, allowing the rest of the tower structure to remain perfectly aligned with wall ties or brackets.

Conclusion

In the field of heavy construction, the fixed Angle steel of tower cranes may seem insignificant, but it is of vital importance to on-site safety and structural integrity. These compact steel supports are the key connection between the tower crane and its concrete base, capable of withstanding huge loads, torques and environmental stresses.

Understanding the significance of the fixed Angle steel for tower cranes and following the correct installation and maintenance norms can significantly reduce the risk of accidents and extend the service life of lifting equipment. Whether you are an installer, a site manager or a purchaser, never underestimate the role of well-installed fixed Angle steel – it is one of the foundations for the safety of on-site cranes.

Related Products

Construction Hoist Floor Calling System

Effortless installation

Reliable performance over extended ranges

Accommodates…

Hoist Intercom

High-strength engineering nylon outer shell (durable)

Easy…

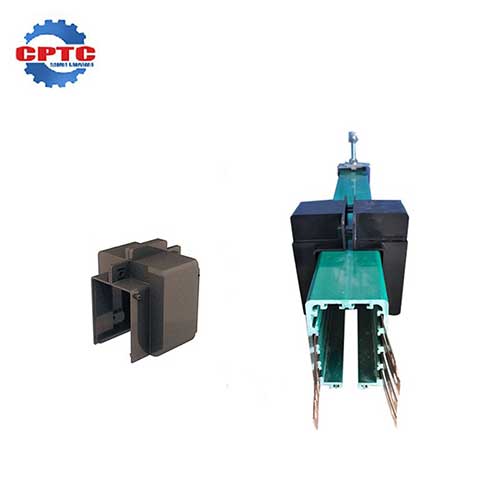

Conductor Bar System

Stability and high…

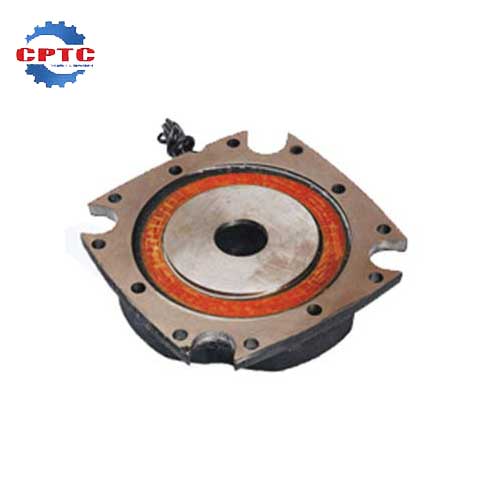

Brake Coil for Construction Hoist

Spring-applied braking;

Precise Coil Resistance;

For 11kw, 15kw,18.5kw motor.