With any high-rise project, time and efficiency are tantamount in the world of building construction. One essential piece of equipment that is used to move workers and materials upwards is the construction hoist. Unlike permanent elevators, these temporary elevators are tailored to specific needs. They are designed to meet safety regulations, performance requirements, safety regulations, and operate at greater heights which is why they are used in high-rise buildings.

This article discusses what construction managers need to pay attention to when working with high-rise building projects. It also explains what features should construction hoists have in order to fit the needs of high-rise projects.

Why High-Rise Construction Requires Specialized Hoists

Basic lifts or traditional hoists are not enough for high-rise construction. Moving workers and heavy materials for traditional buildings is difficult and for multi-storey buildings stretching above meters, it becomes critical.

Here is why refined hoists are needed:

- The increase lifting height need to be efficiently preset for proper travel vertical distance and these advanced hoist systems see to that reliably.

- Load requirement to household a group of workers varies with tasks, exceeding 2,000 kg sometimes along with heaving construction materials.

- Unlike other structures, high-rises take months or even years to build. This demands constant lifting equipment with low downtime.

- Lives are at risk when safety measures are not in place. Stronger braking systems, emergency controls, and anti-fall measures are a must.

- Proper execution tailored to site-specific requirements maximize productivity and advanced worker safety while minimizing construction times.

Types of Construction Hoists Suitable for High-Rise Buildings

Each construction hoist has unique features. Developers typically choose between various hoist types specifically optimized for tall structures based on the building’s size, budget, and timeline.

Rack and Pinion Hoists

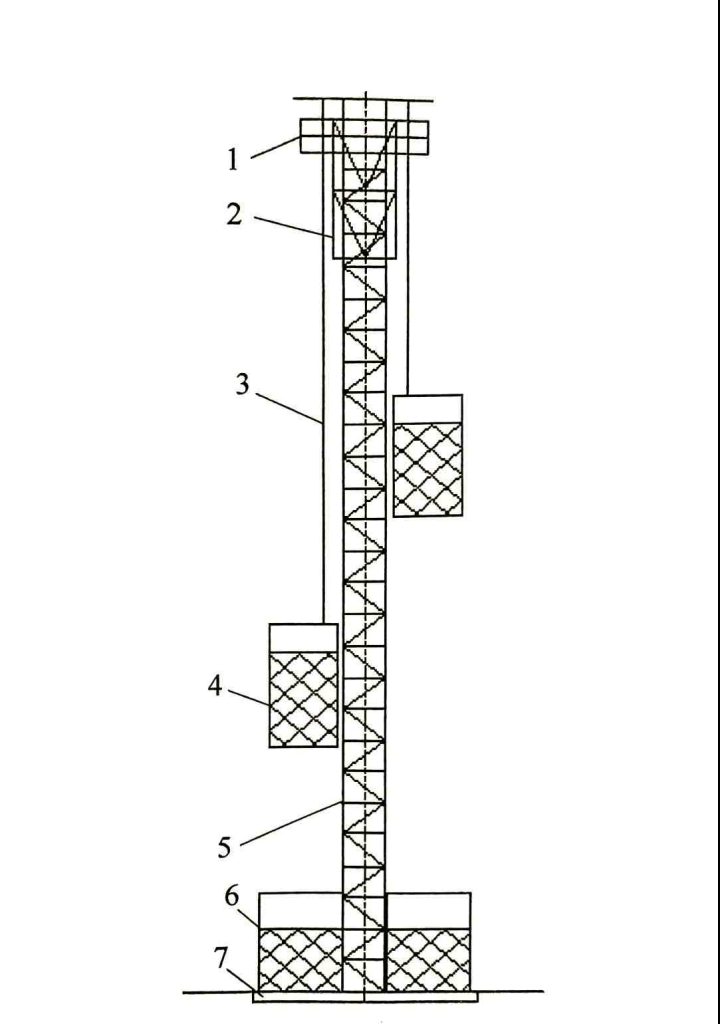

This is the most commonly used construction hoist in high-rise projects. Construction of these hoists involves a gear system that lifts using a pinion gear driving along a fixed rack, which is a toothed track mounted on a mast. Some advantages are:

- Can lift powerfully

- Maintenance and repair is usually simple

As well as being reliable, their performance enables modular expansion as they are easier to maintain and repair than other designs.

Wire Rope Hoists

Use of wire rope hoists is limited to mid-rise or custom built structures as managing long lengths of wires becomes difficult for extremely vertical structures.

- Operational ease

- Usually best suited for lightweight materials

Aside from these, they also require complex anchoring and pulley systems at greater heights which makes them unsuitable for high-rise construction. Thus, for constructing multi-storey buildings, rack and pinion systems are preferred.

Single vs Twin Cage

Twin Cage Construction hoists

Construction hoists are configured either as single or twin cages.

- Single Cage: Ideal for small scale projects or in situations where space is restricted. Has a lower carrying capacity with fewer passengers or materials.

- Twin Cage: Each cage can move independently, greatly enhancing efficiency on the site. One cage can be used for the workers movement while the other is utilized for materials.

For high-rise operations, twin cage hoists usually provide the best return on investment in terms of vertical movement capacity.

Safety Features Required for High-Rise Construction Hoists

Increasing the height of a building increases the risk to the worers, particularly with respect to falls from height, which is one of the most dangerous risks on a construction site. That is why high-rise hoists require advanced safety features.

Key safety components include:

- Limit switches – Prevent over-travel at the top and bottom of the hoist path.

- Over-speed governors – Instantly halt the cage if it descends too quickly, preventing accidents.

- Mechanical and electrical door interlocks – Ensure that doors remain securely closed during movement.

- Anti-fall safety devices – Protect the cage from free fall in case of mechanical failure.

- Emergency brakes – Engage when standard braking systems fail.

- Buffer devices – Installed at the base to absorb impact in emergency landings.

- Overload sensors – Block operation when the load exceeds the hoist’s rated capacity.

- Enclosed cages and mast protection – Protect against wind, debris, and weather.

For high-rise projects, compliance with safety regulations EN12159, ANSI A10.4, or China’s GB10055 is critical when selecting a hoist.

Installation Considerations in High-Rise Projects

The installation of a construction hoist on a tall building requires early planning in the project lifecycle. A few important factors to consider are:

- Wall Ties and Anchoring: A construction hoist must be tied into the structure at regular intervals, usually between 6 to 9 meters vertical spacing. These wall ties mitigate lateral sway and help ensure safety when it comes to structural integrity.

- Shaft vs External Mounting: Hoists can either be placed inside elevator shafts or mounted externally on the building. External mounts have added requirements such as weatherproofing and wind load analysis.

- Scaffold Integration: On some projects, scaffolding systems are integrated with hoists for concurrent transport of materials, workers, and equipment.

- Power Requirements: Most construction hoists used on high rise buildings operate on a 380V or 480V three-phase power system, mandating appropriate electrical infrastructure on the site.

Collaboration with experienced installers is recommended, as improper installation can jeopardize site safety and result in project delays.

Maintenance Requirements at Greater Heights

The higher the hoist climbs, the more critical regular maintenance becomes. High-rise construction hoists are exposed to:

| Impact on Hoist | Recommended Maintenance | Frequency |

| Increased wear, corrosion risks | Inspect protective covers, electrical insulation, and structure | After severe weather |

| Accelerated component fatigue | Daily visual checks on cables, brakes, and motors | Daily |

| Gear clogging, reduced mechanical efficiency | Clean hoist surfaces and apply fresh lubrication | Weekly |

| Loosening of mast and wall tie connections | Inspect mast sections and all wall ties for cracks or looseness | Every 2–4 weeks |

| Delayed schedules, costly repairs | Implement remote monitoring and predictive maintenance alerts | Ongoing (if available) |

Downtime can result in major project delays. Some modern hoists now feature remote monitoring systems, enabling real-time performance tracking and preventive maintenance alerts.

Get Started with the Right Construction Hoist

In high-rise hoist building construction, the construction hoist is far more than a convenience—it’s a lifeline. Selecting the right hoist ensures not only worker safety but also project efficiency and cost control. From choosing between rack and pinion or wire rope systems to understanding safety features and installation protocols, construction managers must approach hoist planning with precision and care.

As high-rise buildings reach new heights in global cities, the need for advanced vertical transport solutions will only grow. Investing in the right construction hoist is a critical step toward successful project delivery.

FAQ

Q1: What is the maximum height a construction hoist can reach?

Modern construction hoists usually operate to a height of 200 meters or more, and some can reach in excess of 300 meters with appropriate mast extensions and wall tie configurations.

Q2: Can construction hoists carry both workers and materials?

Most construction hoists are designed for dual use, featuring both passenger and freight capacities. however, stringent safety regulations has to be observed.

Q3: How long does it take to install a hoist on a high-rise site?

During the initial stages, early planning proves critical; while the installation spans a few days to several weeks, its total duration hinges on the project’s height and complexity.

Q4: What certifications should I look for when buying a construction hoist?

Look for CE (Europe), ANSI (U.S.), GB (China) or local certifications which guarantee safety standard compliance for construction elevators.

Q5: Where can I find a reliable supplier for high-rise construction hoists?

GJJ, Zoomlion and CPTC are well-known for high-rise tailored construction hoists and offer custom solutions. For instance, CPTC provides dependable construction hoists designed for tall buildings with comprehensive installation and after-sales service.

Related Products

GJJ Construction Site Hoist

With a lightweight…

SC Series Frequency Conversion Hoist

Frequency conversion control system.

Smooth starting and braking, less mechanical…

Construction Material Hoist

Use high-quality steel

Simple and cost-saving

Builder Hoist Lift

Flexible

Multifunctional

Easy to operate