Working at heights in construction sites requires a high level of safety, especially when using tower cranes. One critical environmental factor that significantly impacts crane operations is wind speed. Sudden gusts or high wind conditions can endanger equipment, materials, and human lives. To combat this risk, many construction companies now rely on a crucial device: the wind speed anemometer. This compact yet powerful tool plays a vital role in monitoring real-time wind conditions, helping to enhance both safety and operational efficiency.

The Importance of Wind Monitoring in Tower Crane Operations

Tower cranes are often used at heights where wind speed is significantly stronger than at ground level. Even moderate wind conditions can cause loads to sway, increasing the risk of accidents, structural damage, or dropped materials. According to international safety standards (such as those by OSHA or ISO), lifting operations must be halted if wind speeds exceed specific thresholds.

For more detailed information on tower crane construction safety management in windy weather, you can read this article.

This is where wind monitoring becomes essential. Real-time wind data enables crane operators and site supervisors to make informed decisions about when it is safe to proceed with lifts and when to pause operations. Without reliable wind speed data, decisions would rely solely on subjective judgment, which increases risk.

What Is a Wind Speed Anemometer and How Does It Work?

A wind speed anemometer is a device designed to measure the velocity of the wind. In the context of tower cranes, it is typically mounted at the top of the crane or on the jib, where wind impact is the greatest. The most common types used in construction are:

- Cup Anemometers: Measure wind speed based on the rotation of cups.

- Ultrasonic Anemometers: Use sound waves to detect wind speed and direction, offering high precision and durability.

These devices provide either analog or digital output, which can be integrated with the crane’s control system or displayed on a monitor inside the operator’s cabin. Many modern anemometers also include wireless transmission and alarm functions, providing added convenience and safety.

Key Benefits of Using Wind Speed Anemometers on Tower Cranes

The integration of reliable wind speed anemometers into tower crane operations offers a multitude of significant benefits that directly contribute to enhanced safety, improved operational efficiency, and ultimately, the success of the construction project.

Real-time Wind Monitoring

One of the most critical advantages is the provision of immediate, real-time wind speed data directly to the crane operator. Unlike relying on periodic weather reports or visual estimations, the anemometer provides continuous updates on the wind conditions at the height of the crane’s operation. This allows the operator to be constantly aware of the current wind environment. With this up-to-the-minute information, the operator can instantly recognize when wind speeds are approaching or exceeding safe operating limits, enabling prompt and appropriate responses. This real-time awareness is crucial for making dynamic decisions in a constantly changing environment, preventing situations where operations continue unknowingly into unsafe wind conditions.

Real-time Wind Monitoring

One of the most critical advantages is the provision of immediate, real-time wind speed data directly to the crane operator. Unlike relying on periodic weather reports or visual estimations, the anemometer provides continuous updates on the wind conditions at the height of the crane’s operation. This allows the operator to be constantly aware of the current wind environment. With this up-to-the-minute information, the operator can instantly recognize when wind speeds are approaching or exceeding safe operating limits, enabling prompt and appropriate responses. This real-time awareness is crucial for making dynamic decisions in a constantly changing environment, preventing situations where operations continue unknowingly into unsafe wind conditions.

Enhancing Operator Decision-Making

Beyond simply preventing operations in high winds, the anemometer empowers the crane operator with the information needed to make more nuanced and effective decisions throughout their shift. Operators can use the real-time wind data to:

- Plan Lifts: Assess wind conditions before starting a lift, especially for large or sail-like loads, and adjust the lifting plan or timing accordingly.

- Adjust Operations: Modify lifting techniques or speeds in moderate wind conditions to maintain better control of the load and minimize swing.

- Identify Trends: Observe wind speed patterns throughout the day to anticipate potential periods of high wind and plan work schedules more effectively.

- Secure the Crane: Know precisely when conditions require the crane to be placed out of service and secured according to manufacturer instructions (e.g., allowing the jib to slew freely or parking it in a specific direction).

In essence, the anemometer provides the operator with a critical piece of data that, combined with their experience and site-specific knowledge, allows for more informed, safer, and more confident operational decisions.

Improving Project Efficiency and Reducing Downtime

Knowing the real-time and forecasted wind conditions allows project managers to plan lifts more effectively. This minimizes unnecessary downtime and ensures that crane usage is optimized around safe weather windows. As a result, projects can stay on schedule without compromising safety.

Where and How to Install a Wind Speed Anemometer on a Tower Crane

For accurate readings, the anemometer must be installed at a point that is not sheltered by other crane components. The ideal location is:

- At the tip of the jib

- On top of the operator’s cabin (if unobstructed)

- At the highest point of the tower crane mast

Installation usually involves:

- Mounting the device securely using a bracket or flange

- Connecting it to the control panel or display unit

- Calibrating the system to ensure correct readings

Wireless models are easier to install and maintain, as they require no additional cabling and can transmit data directly to remote monitors or mobile devices.

Choosing the Right Wind Speed Anemometer for Your Crane

Not all anemometers are created equal. When selecting a wind speed anemometer for tower cranes, consider the following:

- Measurement Range and Accuracy: Must be capable of detecting both low and high wind speeds with high precision.

- Durability: Should be weatherproof, UV-resistant, and suitable for long-term outdoor use.

- Output Compatibility: Analog or digital output depending on your crane’s monitoring system.

- Alarm Functionality: Audible or visual alarms for high wind conditions.

- Ease of Installation: Especially if retrofitting existing cranes.

The tower crane anemometers supplied by CPTC are widely used on construction sites for tower crane operations, offering high-precision measurement, excellent stability, easy installation, and high reliability. As construction-grade anemometers, they are specifically designed for high-elevation use and harsh environments, making them a smart investment for long-term safety and dependable performance.

Final Thoughts

A wind speed anemometer is not just a simple measuring tool—it is a key safety and productivity device for modern tower crane operations. By providing real-time wind data, preventing dangerous lifts, supporting smarter decision-making, and enhancing project planning, this small instrument plays a big role on construction sites. Whether you’re managing a single crane or overseeing a large-scale high-rise project, integrating a reliable wind speed anemometer into your equipment setup is a smart, safety-first investment.

Related Products

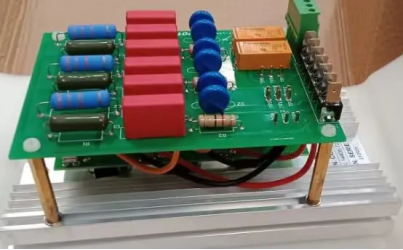

Wind Speed Anemometer

High-precision measurement

High reliability

Easy installation

Potain Replacement Parts

Potain replacement parts;

Potain compatable parts.

Part number: C-61406; B-70406;…

Anti-Collision System for Tower Crane

Visualized Monitoring

Improved Construction Efficiency

Tower Crane Load Limit

Safe and Reliable

Simple Operation

High Precision