Did you know that 70% of tower crane failures originate from issues in the hoisting system? At the heart of this critical system lies the hoisting reducer, a component responsible for ensuring safe and efficient lifting operations. Whether you’re a construction manager, engineer, or equipment buyer, understanding how this device works can prevent costly downtime and enhance worksite safety.

In this article, we’ll explore how this crucial component works, what it consists of, why it matters, and how to ensure its reliable operation.

What Is a Hoisting Reducer in a Tower Crane?

A hoisting reducer is the powerhouse of a tower crane’s lifting mechanism. It converts the high-speed, low-torque rotation from the electric motor into low-speed, high-torque output to lift heavy loads safely. Unlike traditional pulley systems, modern reducers offer 40% higher energy efficiency and precision control, enabling smooth operation even when handling multi-ton materials.

Key Functions:

- Speed Reduction: Reduces motor speed from 1,500 RPM to 5–30 RPM at the output shaft.

- Torque Amplification: Boosts torque by ratios up to 200:1 (e.g., converting 500 N·m input to 100,000 N·m output).

- Load Control: Works with sensors and inverters to maintain precise positioning (±2 cm accuracy).

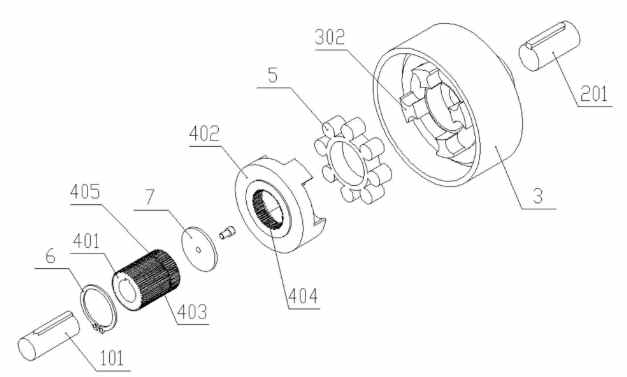

Key Components of a Tower Crane Hoist Reducer

A hoisting reducer is a complex assembly of precision-engineered parts working in concert. While designs vary (e.g., helical, planetary), the core components generally include:

Gearbox Assembly

The core of the hoisting reducer is its gearbox, which contains multiple gears arranged to achieve the desired reduction ratio. These gears are often helical or planetary in design to provide smoother operation and greater load-carrying capacity. The gear arrangement determines how efficiently the reducer converts speed to torque, which is crucial for heavy lifting tasks.

Braking System Integration

To ensure safety during lifting and lowering, the hoisting reducer is integrated with a braking system. This system allows for controlled stopping of the load and prevents unintended descent in the event of power failure or operational error. Modern braking systems can also provide dynamic braking for smooth deceleration.

Lubrication System

Friction and heat are natural byproducts of gear movement. A dedicated lubrication system ensures that all moving parts remain well-lubricated to minimize wear and dissipate heat. Proper lubrication not only extends the lifespan of the gears but also enhances overall performance and reliability.

How Does the Hoisting Reducer Work?

When the hoisting motor is activated, it generates high-speed rotation. This rotational energy is transferred into the reducer, where it passes through a series of gears. Each gear set reduces the speed and multiplies the torque, resulting in a powerful yet slow and stable rotation of the hoisting drum.

The hoisting drum winds or unwinds the steel wire rope, which is attached to the load via a hook or lifting mechanism. By precisely controlling the speed and direction of the drum’s rotation, the hoisting reducer enables safe and accurate positioning of loads.

Why Is the Reducer So Important in Tower Crane Hoisting?

The hoisting reducer is not just a component; it’s fundamental to the crane’s ability to perform its primary task safely and effectively. Its importance stems from several key contributions:

Ensures Stable and Controllable Lifting of Heavy Loads

This is its most obvious and critical function. Without the massive torque multiplication provided by the reducer, the standard electric motor would be utterly incapable of lifting the rated loads of a tower crane.

Furthermore, the speed reduction allows the operator to lift, lower, and position heavy loads with precision and control, which is essential for safety and efficiency on a busy construction site. Slow, steady movement prevents dangerous load swinging or jarring.

Prevents Mechanical Shock Caused by High-Speed Rotation

Directly connecting a high-speed motor to the hoist drum would result in excessively fast and jerky lifting speeds. Starting and stopping would impart significant inertial shocks to the wire rope, the crane structure (boom, tower), and the load itself. The reducer ensures a smooth, manageable operating speed, mitigating these damaging forces.

Extends Service Life of the Hoisting Mechanism

By ensuring smooth operation and preventing shock loads, the reducer helps protect not only itself but also other critical components like the motor, wire rope, drum, bearings, and even the crane’s structural elements. The controlled application of force reduces stress and fatigue, leading to a longer operational lifespan for the entire hoisting system.

Works with Inverters/Frequency Converters for Smooth Starting and Braking

When paired with modern inverter technology, hoisting reducers enable variable speed control, soft start, and regenerative braking—further enhancing safety and energy efficiency.

Top 3 Common Failures & Solutions

| Failure | Causes | Solutions |

| Abnormal Noise | Broken gear teeth or bearing damage | Replace gears with 18CrNiMo7 steel; use SKF bearings. |

| Oil Overheating | Clogged filters; insufficient oil | Clean oil passages; switch to synthetic oil. |

| Output Shaft Vibration | Misalignment (>0.1mm deviation) | Realign with laser calibration tools. |

Case Study: A German construction site avoided $18,000 in downtime costs by detecting misalignment early via vibration sensors.

Looking for a Reliable Hoisting Reducer for Your Tower Crane?

Choosing the right hoisting reducer is critical for your tower crane’s performance and safety. At CPTC, we specialize in high-quality tower crane hoist reducers designed for maximum durability, efficiency, and compatibility with a wide range of crane models. Whether you need a standard reducer or a custom-built solution, our team can help you find the perfect fit for your lifting operations.

Contact us today to learn more about our products or to request a free quote!

Related Products

Sew Motor & Sew Gearbox

SEW drive experts

Customized and efficient

Innovative and energy-saving

Nord Motor & Nord Gearbox

Quality assurance

Rich products

CPTC supply

Slewing Reducer for Tower Crane

Best quality based on…

Slewing Motor for Tower Crane

Ensures stability and safety

Essential for construction sites

Handles heavy materials