Construction sites today must operate efficiently and safely, which means utilizing equipment like construction hoists that help move workers and materials vertically across levels. With rising demand comes more manufacturers offering a range of options; selectinging one carefully can make or break projects.

No matter whether you’re purchasing from global brands or Chinese manufacturers, when making informed decisions about construction hoist suppliers it is crucial not to base them solely on price and appearance alone. Here we explore seven key considerations when selecting construction hoist suppliers–including what red flags to avoid and some of the industry’s most reliable names.

7 Key Factors to Evaluate

An exhaustive evaluation process should be employed when selecting a manufacturer to meet your specific project requirements while upholding the highest safety and quality standards.

1. Certifications and Industry Compliance

At its core, any reputable construction hoist manufacturer must comply with national and international standards pertaining to quality management (such as ISO 9001), CE certification for European markets (CE certification) as well as other certifications like TUV or SGS which assess product safety and performance.

2. Manufacturing Experience and Reputation

Experience is of the utmost importance; manufacturers with longstanding track records tend to produce quality products and professional services. Look for suppliers with equipment supplied for major infrastructure, high-rise buildings, or overseas projects as examples of reliable companies. When making this choice, always ask questions such as these to determine whether this manufacturer fits your criteria for reliability:

- How long has the manufacturer been operating?

- Have you worked with international contractors?

- Do they offer client testimonials and project references?

Strong brand recognition in the market signals consistent performance, and an established manufacturer will more likely provide long-term support.

3. Product Quality and Technical Specifications

While design and appearance are important, the real value lies in product performance. Key parameters to evaluate include:

- Load capacity and lifting speed

- Gear type (gear rack vs. wire rope)

- Material quality (e.g., galvanized steel, rust-resistant coating)

- Control system features (PLC control, overload protection)

- Safety mechanisms and emergency stops

Match technical specs to project demands:

| Parameter | High-Rise Buildings | Tunnel Projects |

| Load Capacity | 2,000–3,200 kg | 1,600–2,000 kg |

| Lift Speed | 0–96 m/min | 0–64 m/min |

| Mast Section | 650×650 mm | 500×500 mm |

Recommended Manufacturers

To assist in your search, here are some of the most respected construction hoist manufacturers in the industry:

Alimak (Sweden) – A globally recognized premium construction hoist manufacturer, known for advanced technology and high safety standards.

GJJ (China) – One of the top construction hoist China manufacturers, with a significant share of the domestic and global market. GJJ products are known for affordability and broad applicability.

GEDA (Germany) – Specializing in precise engineering and exceptional product stability, GEDA is a trusted brand for European and international projects.

CPTC (China) – An emerging leader in high-performance construction hoists, CPTC focuses on innovation, global service, and excellent cost-performance ratio. Their equipment is widely used in high-rise building construction, infrastructure projects, and industrial installations worldwide.

4. Safety Features and Protections

Construction sites are inherently risky environments, making safety non-negotiable. Always check that the construction hoist includes essential safety features such as:

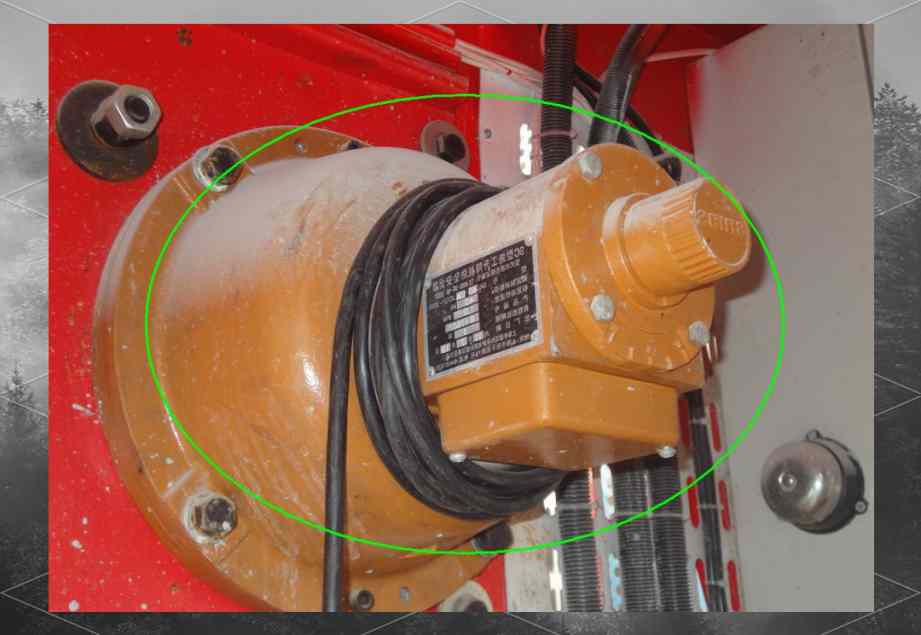

- Anti-fall safety devices

- Mechanical and electrical limit switches

- Emergency stop buttons

- Overload protection

- Safety interlocks and automatic door locks

5. Production Capacity and Lead Time

Project delays due to equipment delivery issues can be costly. Assess the manufacturer’s production scale and delivery reliability:

- Do they own a modern factory with advanced production lines?

- Can they meet your timeline for batch delivery?

- Do they offer modular production for faster deployment?

6. After-Sales Service and Technical Support

Hoist manufacturers provide comprehensive after-sales support that extends beyond delivery of their hoist. This should include services such as:

- Installation and Commissioning Support: Professional technicians offer assistance during initial setup. Operator Training: Training should ensure site personnel operate safely and efficiently.

- Maintenance Services: Comprehensive preventive maintenance plans and prompt support for corrective repairs should be readily available, while genuine spare part availability should also be readily accessible for minimizing downtime. Inquire into their inventory and distribution network.

- Troubleshooting and Technical Assistance: Our trained field technicians offer responsive technical support services to help diagnose and address issues as soon as they arise. Warranty: To fully understand the terms and duration of a hoist and component warranty.

Manufacturers with extensive global or regional service networks can provide faster and more effective support, mitigating project delays and costs associated with hoist downtime.

7. Cost and Value for Money

Although cost should always be taken into account when selecting a hoist manufacturer, its sole determining factor should not be cost itself. Instead, pay attention to how well value for money offered by manufacturers; initially inexpensive hoists may turn out more costly due to frequent breakdowns, maintenance expenses or reduced lifespan compared to more costly models.

Consider the total cost of ownership (TCO) over the expected life of a hoist, including purchase price, installation costs, energy consumption costs, routine maintenance expenses, potential repair expenses and downtime if it breaks down. A higher-quality hoist from a reliable manufacturer might have a higher initial price but result in reduced TCO due to greater reliability, durability, energy efficiency and longer service life.

Warning Signs: 5 Red Flags to Avoid

Not all manufacturers meet industry standards. Here are five warning signs that you should steer clear of:

Refuses to provide third-party inspection reports

Without external verification, you can’t be sure of the product’s real quality.

Maintenance contracts with hidden charges

Unclear service terms can lead to unexpected costs later.

Core components lack traceable serial codes

This makes it difficult to verify quality, origin, or authenticity.

Engineer certifications are expired

Technicians without valid certifications may not be qualified for proper installation or service.

No real test yard, only showroom display machines

If a factory can’t demonstrate live testing or operational units, it may signal poor quality control.

Always ask detailed questions and request documentation when evaluating any manufacturer.

Conclusion

Selecting the right construction hoist manufacturer isn’t just about finding a product—it’s about building a partnership that supports your project goals. By focusing on the seven critical factors outlined above, you can confidently identify trustworthy construction hoist manufacturers that deliver safety, performance, and long-term value.

Related Products

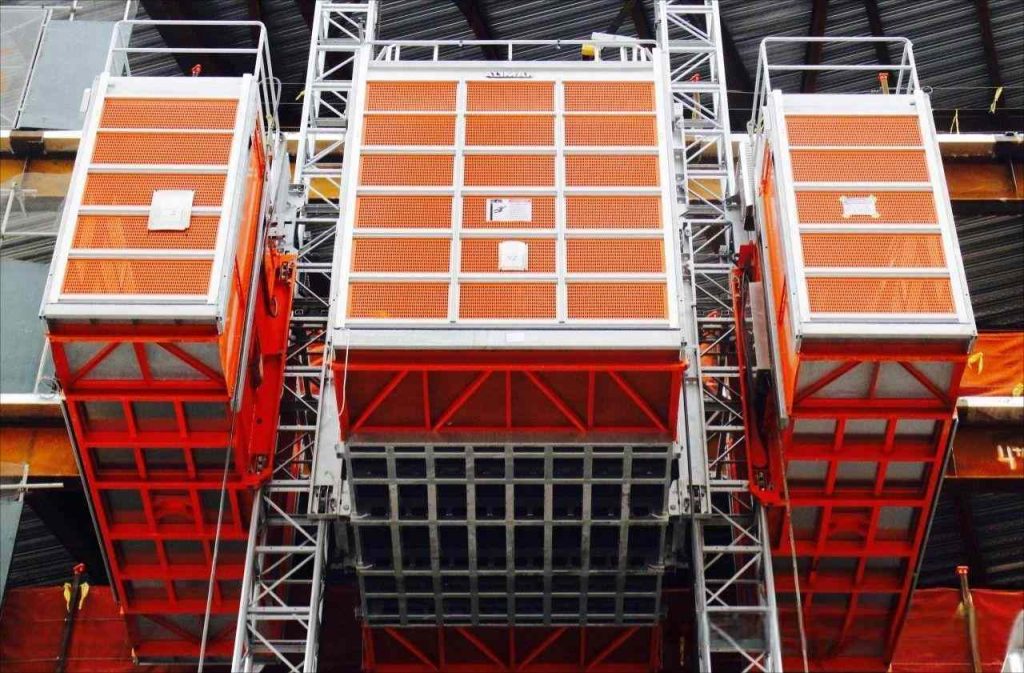

Builder Hoist Lift

Flexible

Multifunctional

Easy to operate

Construction Material Hoist

Use high-quality steel

Simple and cost-saving

Lean Construction Hoist Lift

Compact structure

Easy to operate

Easy to assemble and disassemble

GJJ Construction Site Hoist

With a lightweight…